Most Americans take for granted the federal

government’s role in protecting workers from

injuries that might occur on the job. The popu-

lar notion is that, without the Occupational

Safety and Health Administration and its sister

agency, the Mine Safety and Health

Administration, some companies, perhaps many,

would not invest in safety, which would lead to a

rise in workplace accidents in the United States.

The problem with the popular perception is that

it is based more on faith in beneficent govern-

ment than on facts about government interven-

tion in workplace safety.

Although MSHA has claimed success, there is

no reliable evidence indicating that the Federal

Mine Safety and Health Act of 1977 has made

the nation’s mines any safer. It is actually more

likely that the act’s substitution of rules for

results, of government vigilance for employee

vigilance, and of sanctions for cooperation has

slowed the historic trend toward safer mines.

Despite the questionable benefits bestowed by

the act, special interest groups and MSHA have

successfully defended it against proposals for

reform. As a result, consumers and taxpayers are

left paying the substantial direct and indirect

costs of federal intervention.

The best solution may be to repeal the Mine

Act. Contrary to popular belief, there are sub-

stantial incentives in place that encourage mine

operators to make investments in safety. One of

the most notable incentives is the compensating

wage differentials that miners demand for

undertaking more hazardous work. By respect-

ing the risk-for-pay decisions made by individual

miners, the federal government might be able to

achieve its objective of making the nation’s

mines safer.

Saving Lives or Wasting Resources?

The Federal Mine Safety and Health Act

by C. Gregory Ruffennach

_____________________________________________________________________________________________________

C. Gregory Ruffennach is an attorney specializing in mineral law in Durango, Colorado.

Executive Summary

No. 453

September 19, 2002

We shall not grow wiser before we learn

that much that we have done was very

foolish.

—F. A. Hayek

The 1977 Federal Mine Safety and Health

Act (hereinafter Mine Act), which is rapidly

approaching its 25th anniversary, was passed

by Congress “to provide a more effective

means” of preventing death and serious phys-

ical injury in the nation’s mines.

1

To that end,

the act created a federal law enforcement

scheme consisting of regulation, inspection,

and sanction. The tripartite forced compli-

ance scheme was supposed to be more effec-

tive, not only than its forerunner, the Federal

Coal Mine Health and Safety Act of 1969

(hereinafter Coal Act), but also than the other

federal mining laws that preceded it. Prior to

the 1969 Coal Act, the federal government did

not take a forced compliance approach to

mine safety. Although the Bureau of Mines,

which was created as a federal agency in 1910,

had limited enforcement authority at certain

coal mining operations by 1952, it was pre-

dominantly an informational agency.

The Labor Department, whose Mine

Safety and Health Administration is charged

with implementing the Mine Act, has always

maintained that the forced compliance

approach required by the act has been more

effective than the informational approach

taken by the Bureau of Mines. In fact, former

labor secretary Robert Reich has gone so far

as to hold out the Mine Act as the epitome of

effective government enforcement:

It’s become fashionable lately to dump

on Washington, to say the federal gov-

ernment is just too nosy, too demand-

ing, makes too many rules. The triumph

of the mine safety and health program

serves to remind us of the good that

government can do.

2

Similarly, Davitt McAteer, who held the top

spot in MSHA under the Clinton adminis-

tration, has repeatedly boasted that the Mine

Act is a “scheme that works.”

3

Regardless of whether or not it is fashion-

able to “dump on” the federal government as

Reich contended, it is certainly not fashion-

able to question the federal government’s law

enforcement role in mine safety. As Rep. Cass

Ballenger (R-N.C.), chairman of the House

Subcommittee on Workforce Protections,

noted during a congressional hearing on the

Mine Act in 1998,

I am well aware of the fact that even to

raise these issues is to invite criticism

and demagogue, as being uncaring

about miners, especially underground

coal miners, whose work, I know, is haz-

ardous and difficult.

4

Ballenger was speaking from experience

because, three years earlier, his modest pro-

posal to reform the Mine Act along with the

Occupational Safety and Health Act of 1970

was characterized by organized labor as “the

Workplace Death and Injury Enhancement

Act (DIE Act).”

5

Nonetheless, after more than a quarter of a

century of federal policing of the nation’s

mines, it is appropriate to attempt to deter-

mine whether the Mine Act has provided a

more effective means of preventing miner

deaths and injuries than did the information-

al approach that predated it. The determina-

tion is legitimate not only from a statutory

perspective but also from the larger perspec-

tive of wisely allocating society’s scarce

resources. Although proponents of the Mine

Act often tout its purported lifesaving features

and even attempt to identify specific individu-

als who could have been saved with more vig-

orous enforcement,

6

it is essential to keep in

mind that the resources dedicated to the pro-

tection of adult miners at the workplace are

resources that cannot be used for other pur-

poses, such as preventing the accidental

deaths of children at home. While “we might

all be happier in a world where there were no

such constraints to force us into choices and

trade-offs that we would rather not face,”

7

the

fact of the matter is that, in a world with finite

resources, such tradeoffs are inescapable.

2

Resources

dedicated to the

protection of

adult miners at

the workplace

are resources

that cannot be

used for other

purposes.

Forced compliance has not been more effec-

tive in preventing death and serious physical

injury in the nation’s mines than the policy of

information that preceded it.

8

Since the turn of

the 20th century, fatalities in the nation’s mines

have been steadily declining irrespective of fed-

eral police intervention. In fact, on a fatality per

million ton basis, it appears that the trend

toward fewer fatalities in the coal mines actual-

ly slowed after the forced compliance approach

was introduced.

Although that observation may come as a

surprise to people like Reich, who believe in

the capable beneficence of the federal gov-

ernment, it will not surprise those in the min-

ing industry who recognize that forced com-

pliance does not equate to improved safety.

The Mine Act attempted to resolve a per-

ceived, but probably not real, economic prob-

lem with a legalistic solution. The legalistic

approach, which substituted rules for results,

inspector vigilance for employee vigilance,

and sanctions for cooperation, was inferior,

in every respect, to the informational

approach taken by the Bureau of Mines.

Obviously, a legalistic approach that

yields no measurable benefits in terms of

lives saved while diverting resources from

wealth creation and even safety-related activ-

ities is not the best use of societal resources.

In this regard, the necessary corollary to the

sentiments expressed by Reich is that any

“good that the government can do” is only

good for those who reap the benefits. The

Mine Act benefits Labor Department

employees, organized labor institutions,

large unionized mine operators, and, of

course, attorneys,

9

to the detriment of the

people who might otherwise benefit if those

resources were put to other uses.

Because the Mine Act fails to achieve its

stated objective and squanders society’s

scarce resources, Congress should repeal, or

at least significantly amend, it.

10

In the

absence of federal policing, responsibility for

the safety of the nation’s mines would fall on

American society, state and local govern-

ments, and ultimately the individuals who

make up the mining industry. In the event

that there is a demonstrated market failure

once the forced compliance approach is

abandoned, the federal government should

limit its role to the tried and true approach of

providing information and, perhaps, creating

monetary incentives for additional invest-

ments in workplace safety. However, law

enforcement, in the limited circumstances in

which it is appropriate, should be left to local

authorities, which are accountable to the

communities that they serve.

The Emotional Origin of

Safety Regulation

The origin of federal police intervention

in the nation’s mines was, in large part, the

November 1968 explosion in Farmington,

West Virginia, that fatally injured 78 coal

miners.

11

Unfortunately, the Farmington

explosion was not the first or even the worst

coal mine disaster in our nation’s history.

According to MSHA, “the deadliest year” in

U.S. coal mining history was 1907, when

3,242 deaths occurred and a single mine

explosion killed 358 people near Monongah,

West Virginia.

12

Despite the tragic number of

deaths, mine disasters, such as Farmington

and Monongah, were not even the largest

contributors to the loss of life in the nation’s

coal mines.

13

The Farmington disaster was special

because it was the first mining disaster that

received nationwide media coverage.

According to one account, “The resolution of

the disaster . . . played out in the living rooms

of America” and “created a media circus that

would measure up to anything generated

since.”

14

Congress, responding in large part to the

publicity that the disaster received, convened

hearings on coal mine safety and health. The

focus of the congressional hearings was not

on the testimony of safety professionals,

actuaries, statisticians, and economists but

on the testimony of “daughters and wives” of

coal miners who had perished in the

Farmington mine.

15

Such emotional testimo-

3

Forced compli-

ance has not been

more effective in

preventing death

and serious phys-

ical injury in the

nation’s mines

than the policy of

information that

preceded it.

ny may have been appropriate to help a griev-

ing nation, but it was not an appropriate

foundation for a national workplace safety

and health policy, which it ultimately

became.

The Basic Economics of

Safety

Before 1969 the federal government had

taken, for the most part, a market-based

approach to mine safety.

16

In a market-based

approach, prices, which represent the prefer-

ences and values of individuals, are allowed

to determine how much of society’s scarce

resources are dedicated to mine safety.

17

The most obvious and important price

affecting the amount of resources committed

to mine safety is the price that a mine operator

must pay for mine labor. The price of mine

labor reflects, among other things, the risk

preferences of the available labor pool.

18

Where the individuals in the labor pool are

adverse to threats to life and limb, they will

either demand additional compensation, in

terms of pay or benefits, for hazardous jobs or

simply refuse to undertake such work.

19

The “risk premium” that a mine operator

must pay to attract an entire workforce of min-

ers to the mine and keep them there creates an

incentive for the operator to make the mine

safer.

20

Generally, when the price of risk premi-

ums paid to miners exceeds the price of adding

a safety practice or device, a mine operator will

invest in improvements to make the mine safer

in order to avoid paying more for labor.

21

Although research has not revealed any

studies that document the amount of differ-

ential compensation that miners receive for

agreeing to undertake more hazardous work,

it is worth observing that miners are better

paid than nearly all other workers.

22

According to the Bureau of Labor Statistics:

Average earnings in mining and quar-

rying were significantly higher than

the average for all industries. Workers

in underground mines also tend to

earn more per hour than miners on the

surface.

23

The National Mining Association boasts that

“the average miner makes $49,000 per year in

salary, not including overtime, bonuses and

benefits.”

24

Although the price of labor reflects the

risk preferences of individual miners more

than any other price, it is not by any means

the only price that encourages a mine opera-

tor to commit resources to mine safety. As

present MSHA administrator David Lauriski

has noted, “The cost of the average lost work

injury in mining could be on the order of

$10,000 to $30,000 per incident.”

25

The costs

for accidents resulting in injury arise from

investigating and reporting injuries, giving

first aid, losing production, training replace-

ment workers, and paying overtime to unin-

jured workers.

26

Those accident costs create a

strong incentive for a mine operator to com-

mit resources to injury prevention.

27

The price of insurance also creates a sub-

stantial incentive for a mine operator to invest

in accident prevention.

28

In all 50 states, mine

operators are required to maintain workers’

compensation insurance.

29

To a large extent,

the mine operator’s incentive to avoid the insur-

ance costs associated with compensable injuries

is a surrogate for the historical incentive to

avoid tort liability.

30

However, even with the tort

liability protections that state workers’ com-

pensation programs provide, the possibility of

liability to third parties, and even to employees

in certain cases, creates an additional incentive

for mine operators to prevent injuries to

employees.

31

In addition to prevention efforts,

employers generally mitigate those additional

potential liabilities with supplemental insur-

ance. To the extent that workers’ compensation

and supplemental insurance premiums are

experience rated,

32

they create an incentive for a

mine operator to invest in safety.

33

In addition to the direct incentives that a

mine operator has for avoiding injury to its

employees, a mine operator also has an incen-

tive to protect its equipment and facilities.

34

In

the mining industry, which is subject to fire,

4

The “risk premi-

um” that a mine

operator must

pay to attract an

entire workforce

of miners to the

mine and keep

them there creates

an incentive for

the operator to

make the mine

safer.

explosion, and ground failure risks, the costs of

an accident can be extraordinary because of the

equipment and facilities that are sometimes

destroyed.

35

Although losses of equipment and

facilities are generally covered by insurance, the

insurance, to the extent that it is experience

rated, does not reduce the mine operator’s

incentive to focus on loss prevention. More

often than not, the measures that reduce risk to

equipment and facilities have the corollary ben-

efit of reducing risk to miners.

The Informational

Approach to Safety

Regardless of whether its actions were

shaped by principle, political necessity, or inad-

vertence, the federal government’s initial foray

into mine safety focused on improving the mar-

ket for mine safety with information rather

than on displacing the market with police inter-

vention. In 1910 Congress established the

Bureau of Mines as an agency within the

Department of the Interior.

36

The bureau was

“an informational agency,” charged with con-

ducting research and reducing accidents.

37

The

bureau attempted to improve mine safety

through the dissemination of information to

both miners and mine operators.

38

Economic theory, which holds that “better

information can improve the workings of the

market for safety,” predicts that the bureau’s

efforts to disseminate information would

improve safety in the mines.

39

Information is

essential to the proper functioning of the mar-

ket for safety because the risk premiums

demanded by “informed workers merit more

respect than those of uninformed workers.”

40

If

a miner does not recognize and understand the

hazards that he faces at the mine site or erro-

neously assumes that he is exempt from risk,

41

he may not demand an adequate risk premium

from the mine operator. An inadequate risk

premium does not create a sufficient incentive

for the mine operator to invest in safety.

Despite the fact that it is essential to

informed decisionmaking, information has

deviant properties as a market good, which

means that in unregulated markets for safety

there may not be appropriate incentives to

develop and share information.

42

With

respect to the development of safety infor-

mation, Rhea Graham, former director of the

Bureau of Mines, explained,

In these areas [workplace safety and

health], the returns to society [based on

research and development] may be

large, but the returns to the individual

or private company may not be suffi-

cient to encourage investment.

43

For example, although coal mine explosions

accounted for significant loss of life and capital

in the first part of the 20th century, it was the

Bureau of Mines, not mine operators, that

established through study and experimenta-

tion that coal dust contributed as much to the

explosion problem as did methane and that

rock dusting was an effective preventive mea-

sure.

44

With respect to the sharing of safety

information, mine operators with poor safety

records have little incentive to share hazard

information with miners who might demand

higher wages.

45

The Bureau of Mines attempted

to fill the employee information gap, for exam-

ple, by distributing 352,000 “Miner’s Circulars”

to coal miners in 1912.

46

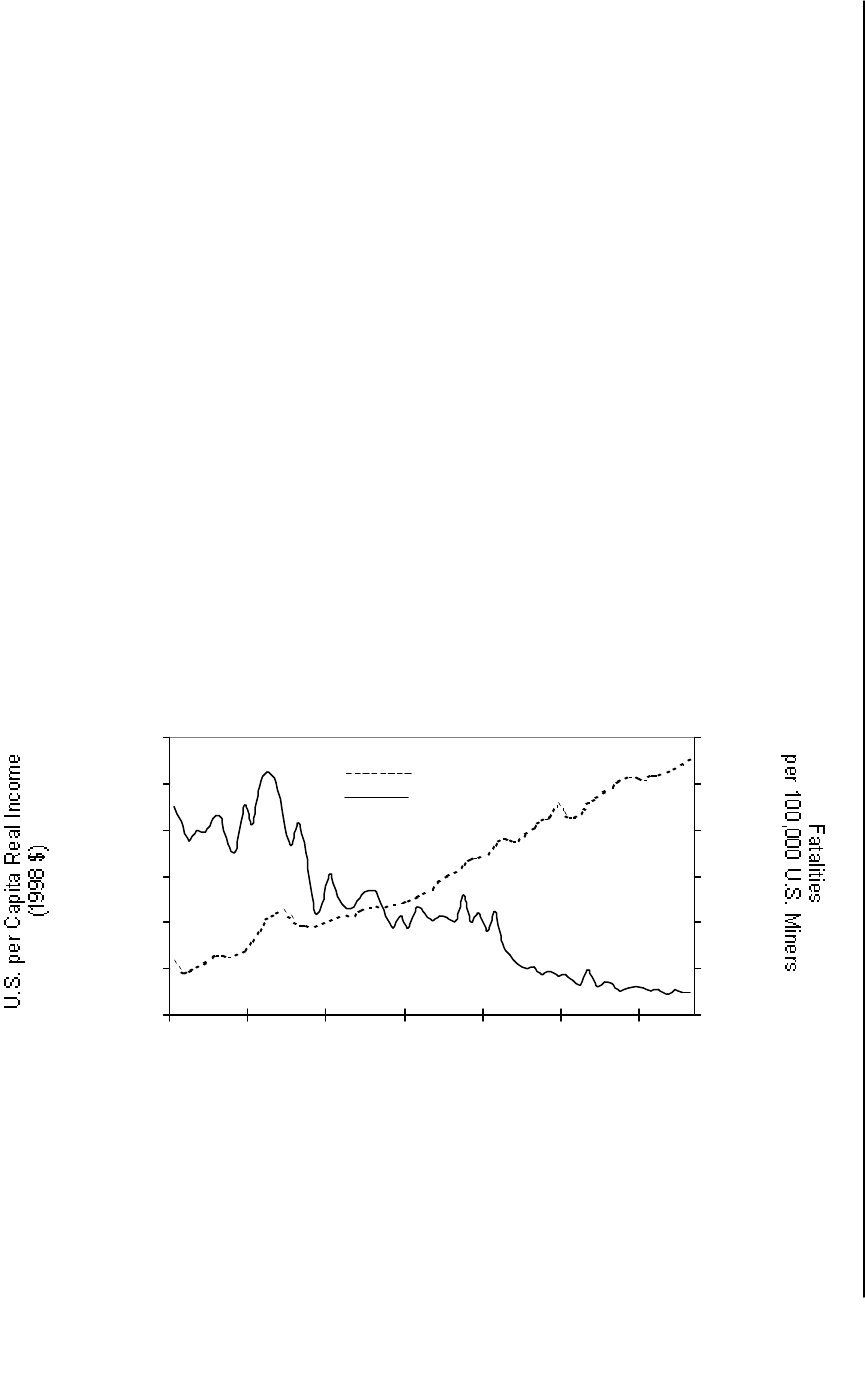

Although research has not revealed any

analysis that shows a statistically significant

correlation between the bureau’s dissemina-

tion of information and an improvement of

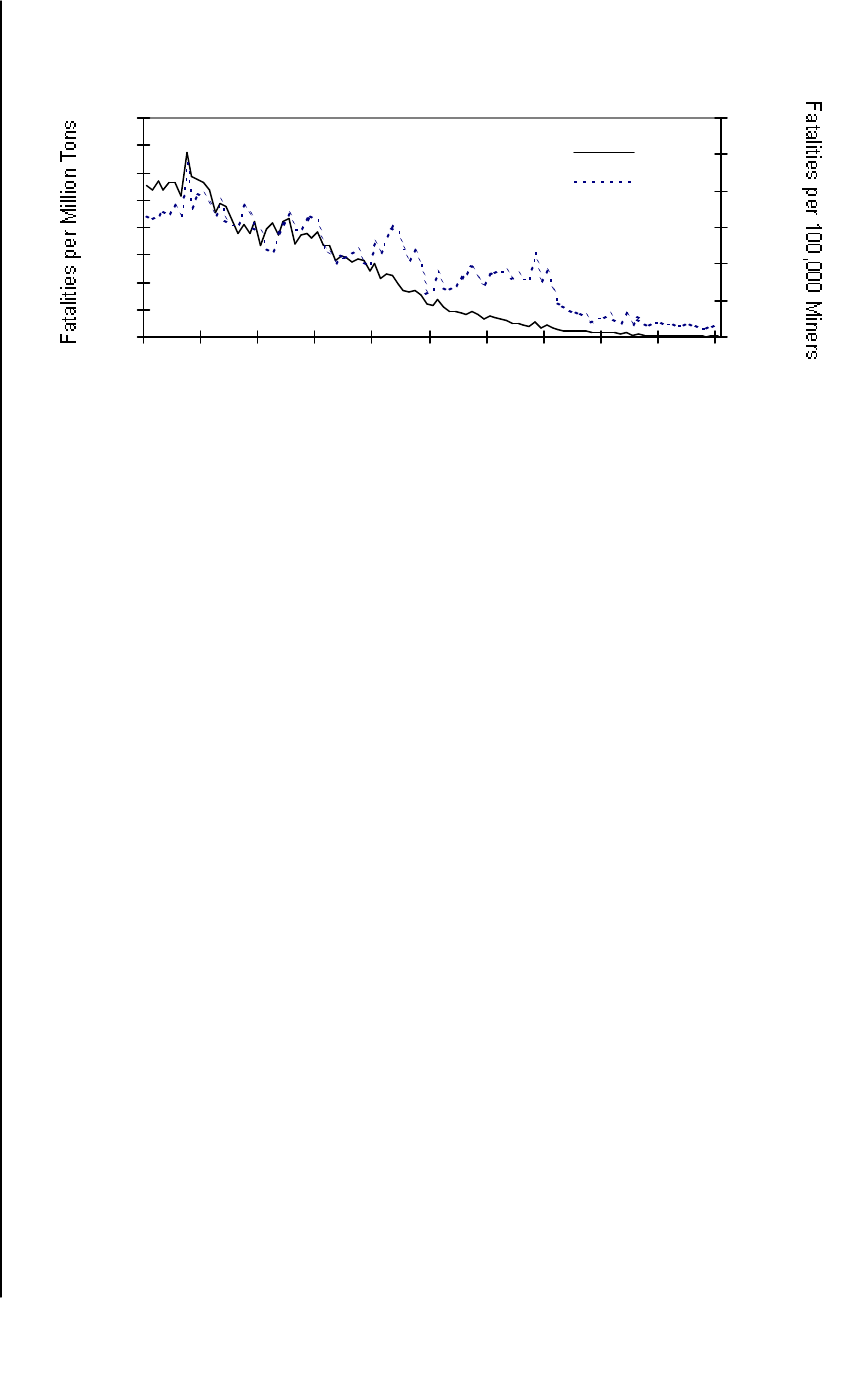

safety in the nation’s mines, Figure 1 shows

that after the bureau’s creation the number

of mine fatalities began a steady descent that

has only recently tapered off.

Although the correlation does not establish

that the Bureau of Mines contributed to the

decline in mine fatalities, specific instances in

which information disseminated by the bureau

directly and positively affected mine safety have

been well documented.

47

Congress granted the bureau greater

authority in the years following its creation,

48

but the bureau’s enforcement authority at coal

and noncoal mines remained minimal.

49

In

1941 the bureau was authorized to enter coal

5

Measures that

reduce risk to

equipment and

facilities have the

corollary benefit

of reducing risk

to miners.

mines, and in 1947 it was authorized to formu-

late a code of federal advisory regulations for

mine safety. The Federal Coal Mine Safety Act

of 1952, which was amended in 1966, and the

Federal Metal and Nonmetallic Mine Safety Act

of 1966 provided for the promulgation of

mandatory standards, inspection and investiga-

tion authority, and the issuance of violation

notices and withdrawal orders. However, under

both acts the imposition of civil sanctions was

limited to cases in which an inspector had been

refused access to a mine or in which there was

noncompliance with an inspector’s withdrawal

order. For the most part, the federal govern-

ment left law enforcement at mining opera-

tions to the individual states.

50

The Illusion of Resource

Misallocation

To a large extent, the 1969 Congress still

considered the problems with mine safety, as

exemplified by the Farmington disaster, to be

economic in nature. Specifically, Congress

determined that the mining industry did not

properly allocate its capital and human

resources. The 1969 Congress explained: “The

way that we mine coal today is not humanitari-

an, resourceful, or efficient. It is inexcusably

wasteful of our most precious asset—the

human being.”

51

Despite the numerous terrible coal mine

disasters that preceded passage of the Coal

Act, it is unlikely that coal mine operators

viewed labor as a resource that was abundant

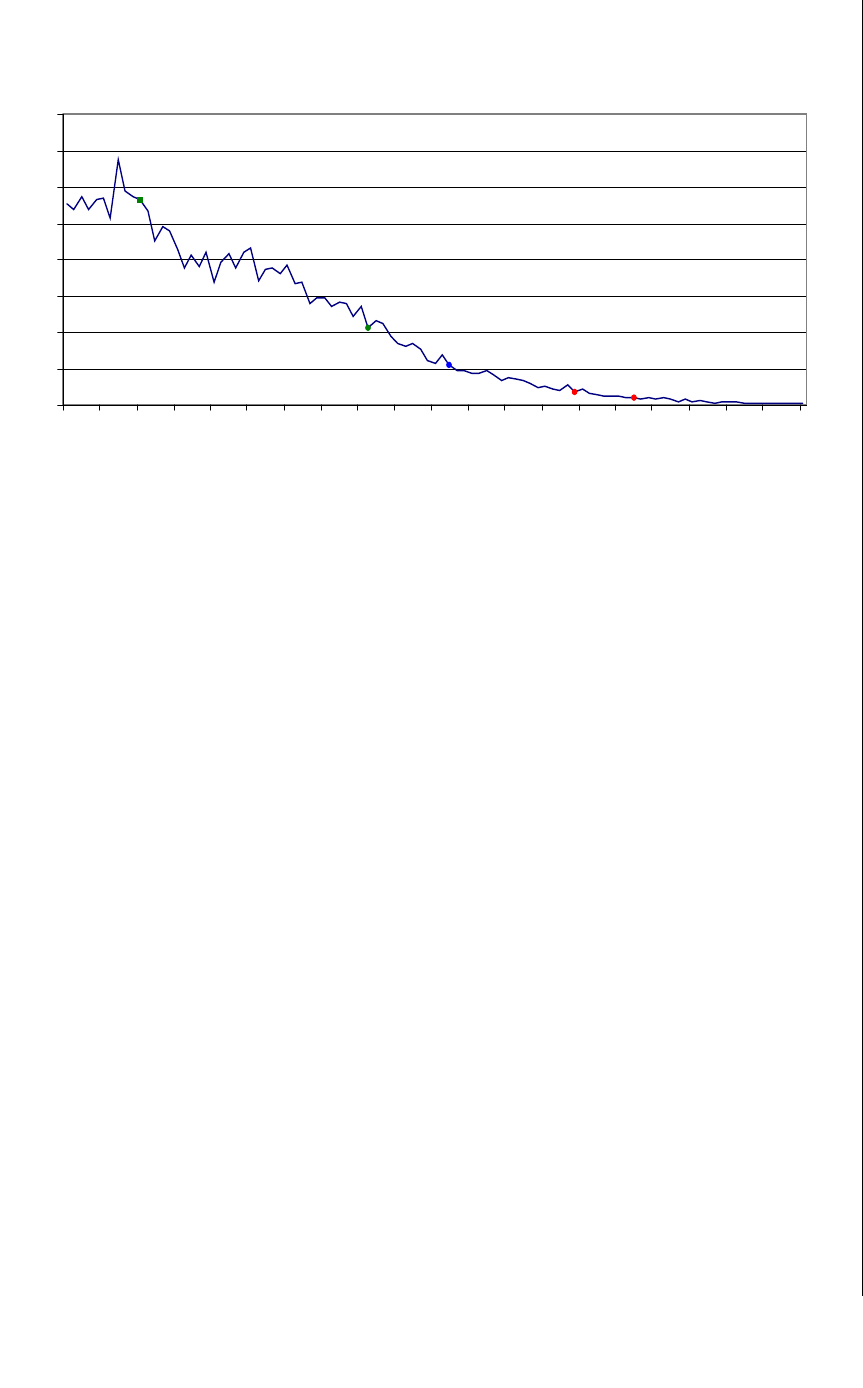

enough to be wasted in 1969. As Figure 2

illustrates, since at least 1950 the coal mining

industry in the United States had been pro-

ducing more tonnage with fewer miners.

The trend suggests, contrary to congres-

sional views in 1969, that coal mine opera-

tors treated mine labor as a scarce resource

that needed to be conserved.

Nowhere is the conservation of coal mine

labor in the United States more evident than in

a comparison between coal mining in China

and in the United States. In China, where labor

is abundant and capital is scarce, it is estimated

that around 20,000 coal miners were fatally

injured while producing about 1.2 billion tons

of coal in 1999.

52

In the same year, in the United

6

The trend sug-

gests, contrary to

congressional

views in 1969, that

coal mine opera-

tors treated mine

labor as a scarce

resource that

needed to be

conserved.

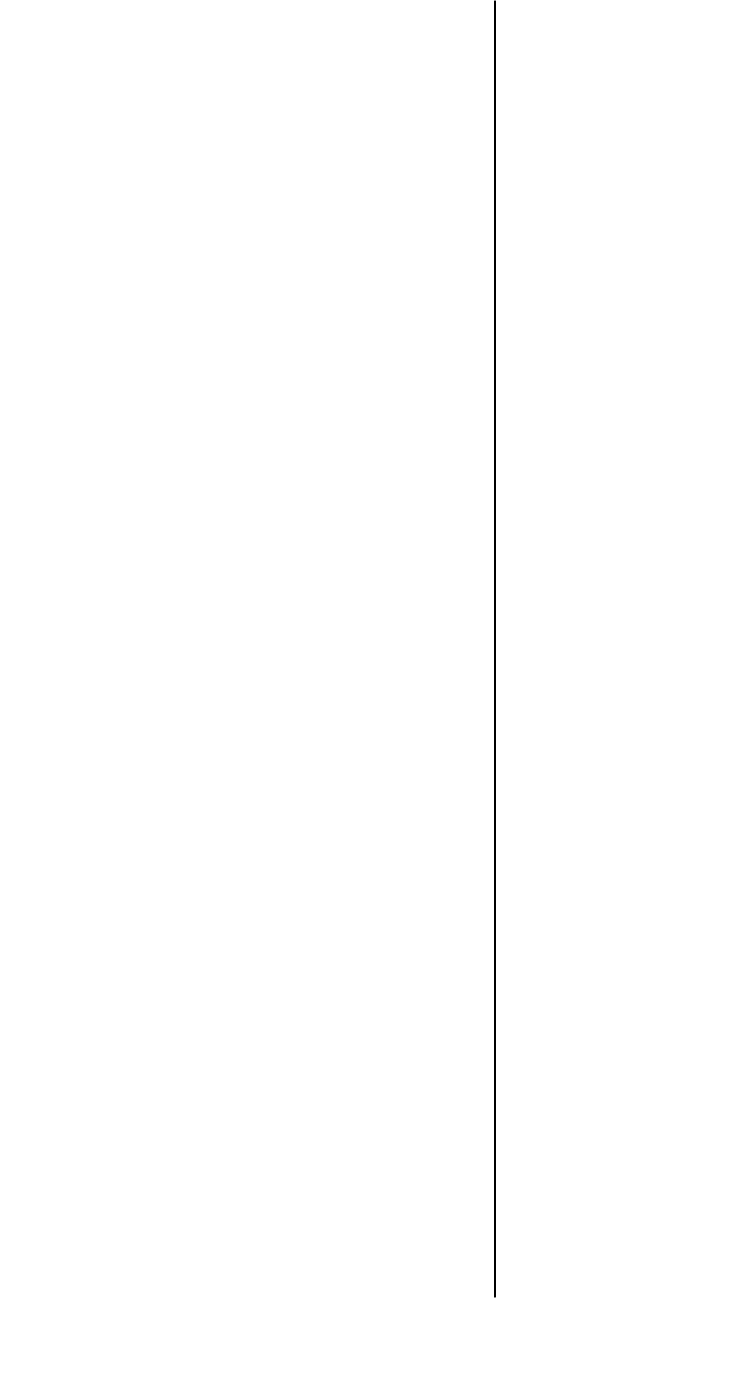

Figure 1

Annual U.S. Mining Fatalities

Sources: Author’s calculation (metal/nonmetal fatalities = coal fatalities) based on data from U.S. Department of

Labor, MSHA Internet, Metal/Nonmetal Fatalities 1900 [1911] through 2001, www.msha.gov/centurystats/mnm

stats.htm; and U.S. Department of Labor, MSHA Internet, Coal Fatalities for 1900 through 2001, www.msha.gov/

centurystats/coalstats.htm.

Coal Act

Mine Act

0

250

500

750

1,000

1,250

1,500

1,750

2,000

2,250

2,500

2,750

3,000

3,250

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

Metal/Nonmetal

Coal

Year

Bureau of Mines

States, where capital is abundant and labor is

scarce, only 29 miners were fatally injured while

producing approximately 1.1 billion tons of

coal.

53

Thus, it appears that the resource allocation

issue that Congress was determined to address

in 1969 may not have been as bad as Congress

made it out to be, if it existed at all. In 1969, 203

coal miners died producing 570,670 thousand

tons of coal; whereas 35 years earlier, in 1934,

1,226 coal miners died producing 416,166

thousand tons of coal.

54

Although Congress

heard it otherwise, the clear trend, for whatever

reasons, was toward conserving the lives of coal

miners.

55

The New Regulatory Road

Ironically, although the 1969 Congress

characterized the problem as one of resource

allocation, it did not opt for an economic

solution to the perceived problem. Instead,

Congress and the Nixon administration,

both of which consisted of more lawyers than

economists, determined that “a strong law is

necessary to protect the men who extract one

of our Nation’s most vital resources.”

56

The

“strong law” was, of course, the 1969 Coal

Act, which put in place a law enforcement

scheme of regulation, inspection, and sanc-

tion for the nation’s coal mines. The Coal Act

assigned “legal rights and duties,” placing the

“duty” to maintain a safe workplace on the

coal mine operator and granting the “right”

to a safe workplace to the coal miner.

57

The 1969 Congress charged the Bureau of

Mines with implementing the new assignment

of safety duties and rights within the nation’s

coal mines. In 1973 the Department of the

Interior transferred the bureau’s new enforce-

ment functions to the Mine Enforcement

Safety Administration.

58

The enforcement pow-

ers transferred to MESA, which at the time of

7

It appears that

the resource allo-

cation issue that

Congress was

determined to

address in 1969

may not have

been as bad as

Congress made it

out to be, if it

existed at all.

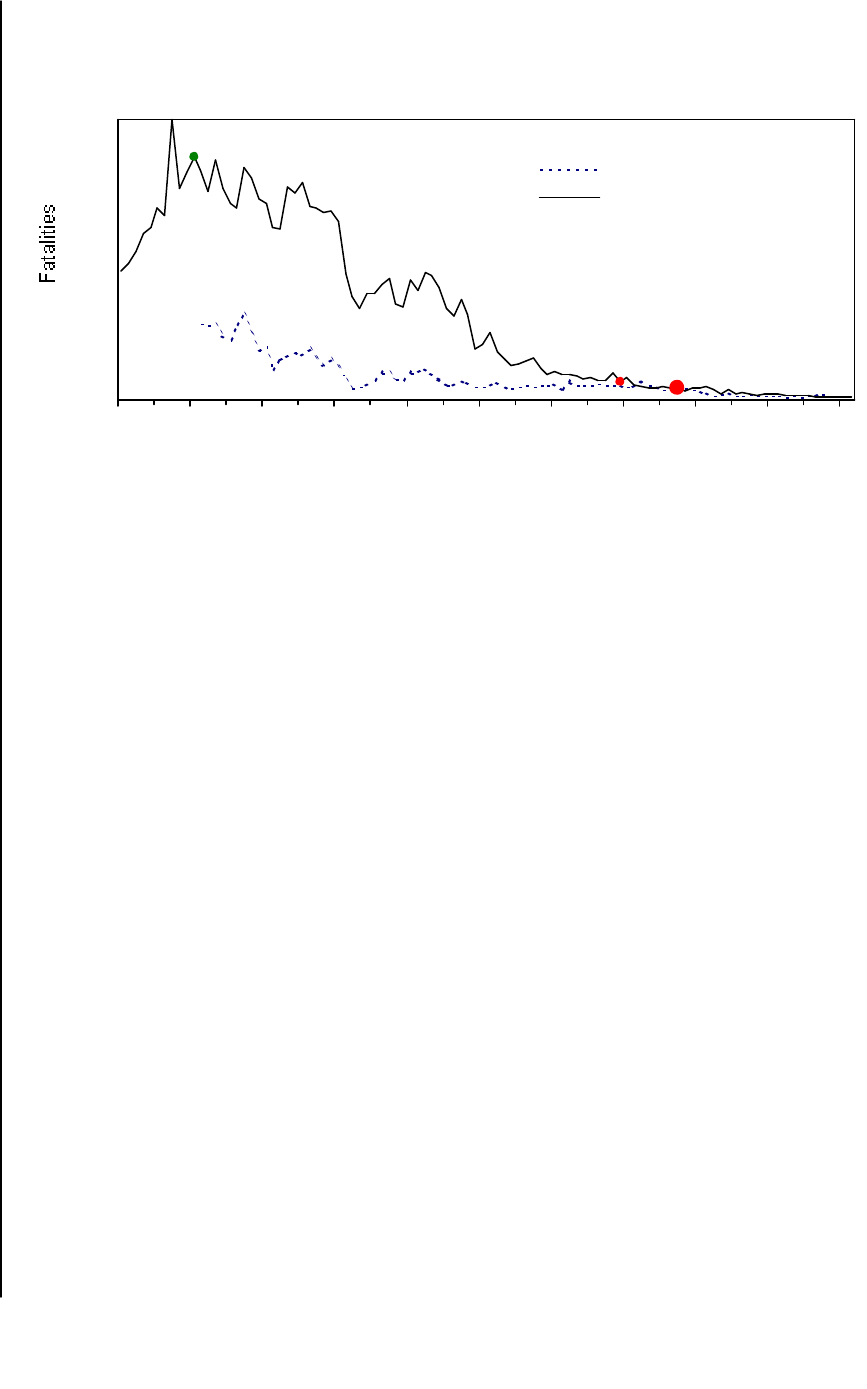

Figure 2

Conservation of Coal Mine Labor

Sources: Number of miners based on U.S. Department of Labor, MSHA Internet, Coal Fatalities for 1900 through

2001, www.msha.gov/centurystats/coalstats.htm; coal production based on data from Energy Information

Administration, Coal Products Publications, Coal Data: A Reference, Table 18, U.S. Production Trends in

Bituminous Coal and Lignite, 1900–1993 (total production, thousand short tons), 1995, pp. 65–66,

http://tonto.eia.doe.gov/FTPROOT/coal/006493.pdf; Pennsylvania Department of Environmental Protection,

Mining and Reclamation, 2000 Annual Report on Mining Activities, Table 1, Anthracite Statistical Summaries

1870 to 2000 (production, net tons), www.dep.state.pa.us/dep/deputate/minres/bmr/annualreport/2000/

table_01.htm (1990 to 1993 anthracite production data); and Energy Information Administration, Coal Products

Publications, Coal Industry Annuals 1994–2000 (thousand short tons), http://tonto.eia.doe.gov/FTPROOT/

coal/coalpubs.htm (1994–2000 coal production data, including Pennsylvania anthracite operations but excluding

silt, culm, refuse bank, slurry dam, and dredge operations).

0

100,000

200,000

300,000

400,000

500,000

600,000

700,000

800,000

900,000

1,000,000

19001905 191019151920 1925 1930 19351940 194519501955 1960 1965 1970 1975 198019851990 19952000

0

200

400

600

800

1,000

1,200

Year

U.S. Coal Miners

U.S. Coal Production

enactment were unique to the Coal Act, includ-

ed the imposition of monetary penalties for all

violations of mandatory federal coal safety and

health standards as well as criminal penalties

for knowing and willful violations of the stan-

dards.

59

The use of “first-instance” sanctions

marked a significant departure from prior fed-

eral policies,

60

which left law enforcement to the

various states and, to a large extent, left mine

safety to the economic marketplace.

Unfortunately, passage in 1969 of the Coal

Act with its forced compliance approach did

not put an end to disasters in the coal mining

industry. As Congress noted in 1977:

At Buffalo Creek, in February, 1972,

125 persons died when a dam burst

sending a near tidal wave of murky

water through the seventeen mile long

valley, while the mining enforcement

agency questioned its authority to reg-

ulate the coal mine impoundment

dam in question.

At Blacksville, in July 1972, nine min-

ers at work behind a piece of equipment

that caught fire were trapped and died in

the mine because those at the scene of the

fire had not been adequately trained in

emergency procedures.

At Scotia, in March, 1976 twenty-

three miners and three Federal inspec-

tors died in two explosions of accumu-

lated methane gas when the mine safety

enforcement effort was unable to detect

and address chronic conditions of inade-

quate ventilation in that mine.

Near Tower City, Pennsylvania, in

February, 1977, nine miners died when

water from an underground source

inundated active workings, sending tons

of water and debris coursing through the

mine.

61

On the basis of those tragedies, the 1977

Congress concluded that “review of . . . six years

of enforcement of the Coal Act, requires the

Committee to report that fatalities and dis-

abling injuries in our nation’s mines are still

unacceptably and unconscionably high.”

62

Having reached that conclusion, the 1977

Congress did not deduce that forced compli-

ance might not meaningfully improve work-

place safety; rather it surmised that a more

stringent law with broader coverage was

required. The 1977 Congress reasoned that

mine operators [must] still find it

cheaper to pay minimal civil penalties

than to make the capital investments

necessary to adequately abate unsafe or

unhealthy conditions. . . .

63

Following that curious reasoning, the 1977

Congress resolved to “strengthen” the 1969

Coal Act.

The Special Interest

Influence

Before the Mine Act was passed in 1977, the

Coal Act provided protection to only the nation’s

coal miners. Congress had determined that “coal

miners deserve the safest, healthiest work envi-

ronment our technology will enable us to pro-

vide,” but it did not make a similar determina-

tion with respect to noncoal miners.

64

However, as is often the case when one

group gets special treatment from the govern-

ment,

65

other groups soon demanded similar

treatment.

66

True to that principle and seven

years after the enactment of the Coal Act, the

United Steelworkers of America complained

that “there is absolutely no reason why miners

in one segment of the mining industry should

be given different statutory rights than miners

in another segment of the industry.”

67

After all,

the May 1972 carbon monoxide asphyxiation

of 91 miners at Sunshine Silver Mine in Idaho

demonstrated, quite horrifically, that death in

the workplace was not unique to coal miners.

68

Actually, there were valid reasons to treat

underground coal miners differently than

other groups of miners. In 1977 underground

anthracite coal miners had significantly higher

injury incidence rates than did all other types of

miners.

69

Nevertheless, organized mine labor

was able to convince Congress that the

8

There were valid

reasons to treat

underground coal

miners differently

than other groups

of miners.

strengthened scheme of regulation, inspection,

and sanction should be extended to all min-

ers.

70

Some scholars opined that, to a large

extent, organized mine labor used the legisla-

tive process to achieve what it had been unin-

terested in achieving

71

at the bargaining table.

72

Thus, with passage of the Mine Act in 1977,

Congress provided special protections for “the

sacred lives of those members of our society

who toil in the mines to keep our country run-

ning efficiently.”

73

However, Congress afforded

less extensive protections under the

Occupational Safety and Health Act of 1970 for

other American workers who toiled in the fac-

tories, fields, and forests to keep our country

running efficiently, despite the fact that some

of those workers were exposed to greater work-

place hazards than even underground

anthracite coal miners.

74

The Neglected

Constitutional Constraints

To a certain extent, however, Congress was

powerless to protect the lives of all miners at the

behest of the labor organizations. The U.S.

Constitution expressly enumerates the powers

of the federal government. One cannot find

among those enumerated powers a power to

police the nation’s mines, or any workplace for

that matter. Though Congress’s intentions to

protect sacred human life were honorable, the

Tenth Amendment of the Constitution

reserves such police powers to the individual

states.

75

The Constitution, however, does grant

Congress the power “to regulate commerce.”

76

Thus, when Congress initially resolved to pro-

tect the lives of coal miners in 1969, it declared,

[T]he disruption of production and the

loss of income to operators and miners

as a result of coal mine accidents or occu-

pationally caused diseases unduly

impedes and burdens commerce.

77

The 1969 declaration was not without prece-

dent or context. In 1940 the federal govern-

ment actually seized the nation’s coal mines to

avert a labor dispute that might have disrupt-

ed the supply of coal during a period of

increasing hostility abroad.

78

In 1969, at the

dawn of the so-called energy crisis, America

was facing concerns about future energy sup-

plies.

79

Even in that historical and geopolitical

context, the specific nexus between interstate

commerce and particular coal mine disasters

was not entirely clear.

The nexus was even less clear in 1977

when Congress expanded the Coal Act to

cover noncoal mines.

80

The reality, in 1977

and even in 1969, was that Congress was

enacting social measures aimed at minimiz-

ing “the grief and suffering of miners and

their families” at the behest of labor organi-

zations and was not especially concerned

about commerce between the states.

81

The Forced Compliance

Approach

Echoing the concerns about resource alloca-

tion first raised in 1969, the “first priority” of

the Mine Act was to establish the miner as the

mining industry’s “most precious resource.”

82

The 1977 Congress, however, did not opt to

increase the value of the miner through eco-

nomic means, such as a tax on injuries.

83

Instead, the 1977 Congress, following the lead

of the 1969 Congress, attempted to protect

miners by granting them legal rights, specifical-

ly “the right to a safe workplace.”

84

To ensure that the right of miners to a safe

workplace was vigorously protected, the 1977

Congress moved MESA from the Department

of the Interior to the Department of Labor and

renamed it the Mine Safety and Health

Administration. Historically, the Department

of Labor, which housed the Occupational

Safety and Health Administration, had been

the governmental entity charged with protect-

ing federal rights granted to workers.

85

MSHA was charged with implementing a

tripartite forced compliance scheme, similar to

but more stringent than the scheme created by

the 1969 Coal Act. First, Congress directed

9

The U.S.

Constitution

expressly enu-

merates the pow-

ers of the federal

government. One

cannot find

among those enu-

merated powers a

power to police

the nation’s

mines, or any

workplace for

that matter.

MSHA to promulgate mandatory safety and

health standards for all of the nation’s mines.

86

Second, Congress required MSHA to enter all

surface mines at least twice a year and all under-

ground mines at least four times a year, without

warrant or notice, to assess compliance with the

federal standards.

87

Third, Congress directed

MSHA to penalize any and all instances of non-

compliance through the use of first-instance

civil fines and criminal sanctions, not only

against mine operators but also against direc-

tors, officers, and agents of mining corpora-

tions as individuals.

88

In passing the Mine Act, the 1977

Congress did not intend the forced compli-

ance approach to augment the market-based

approach that predated the 1969 Coal Act;

rather, Congress intended police interven-

tion to supplant the market for safety. The

1977 Congress believed that its attempt to

eliminate the hazards associated with mining

through forced compliance would be so suc-

cessful that it would actually reduce the labor

costs,

89

injury or downtime costs,

90

and

workers’ compensation costs

91

that had tra-

ditionally created incentives for mine opera-

tors to invest in safety. Simply put, Congress

fully expected forced compliance

[t]o provide more effective means and

measures for improving the working

conditions and practices in the

Nation’s coal and other mines in order

to prevent death and serious physical

harm, and in order to prevent occupa-

tional diseases from originating in

such mines.

92

The Mine Act was supposed to be “more effec-

tive” than not only the Coal Act but also the

market-oriented, informational approach to

mine safety that existed prior to 1969.

The Mine Act Touted as a

Model Law

In 2000, in MSHA’s annual budget request,

Davitt McAteer, former MSHA administrator,

told Congress that “the Federal Mine Safety

and Health Act has been an extraordinarily effec-

tive law.”

93

McAteer did not cite any studies

that established the effectiveness of the Mine

Act to support his sweeping conclusion.

94

In

fact, he offered only one statement that could

arguably be construed as support for his bold

claim of effectiveness:

I am proud to say that the last five years

have been the safest on record for the

U.S. mining industry. It entered the

20th century with the worst safety and

health industrial record in this country

or abroad—we enter this century with

the best mine safety and health record

among major producing countries in

the world, a proud accomplishment.

95

Presumably, because the U.S. mining industry

went from “worst” to “best” in the 20th centu-

ry, Congress was expected to infer that the

Mine Act had been “extraordinarily effective.”

The Labor Department has not always been so

bashful. In 1995, for example, Labor Secretary

Reich told Congress that “coal miners are five

times less likely to be killed on the job than

they were in 1969, and metal miners twice less

likely to die—largely because we had the Mine

Act and MSHA in place.”

96

In fact, Clinton administration Labor

Department officials were so enamored with

the Mine Act’s forced compliance approach

that they vigorously defended it against reform

in the mid-1990s. In 1995 Congress, lead by

Rep. Cass Ballenger, appeared to be ready to test

the waters with a modest reduction of MSHA’s

enforcement authority, justified on cost-cut-

ting grounds, as part of the Republican Party’s

Contract with America.

97

However, the Labor

Department vigorously defended the statute as

originally enacted in 1977. McAteer told

Congress:

The dramatic improvements in mine

safety and health are proof that the Mine

Act and MSHA are working. We do not

claim sole credit for the success of the last

twenty-five years. . . . There are many fac-

10

In passing the

Mine Act, the

1977 Congress

intended police

intervention to

supplant the mar-

ket for safety.

tors that help explain why things have

improved. It is clear, however, that without

federal intervention, conditions in the mines

would not have improved.

98

The Labor Department, which was support-

ed by organized labor

99

and even by some

large mine operators, successfully defeated

the reform initiative with the help of a veto

threat from President Clinton.

100

Oddly, the 1995 Congress, still in its cost-

cutting mode, subsequently decided to elimi-

nate the Bureau of Mines, which, unlike

MSHA, did not have police powers.

101

At the

time the bureau was eliminated, there were

legitimate questions about whether large min-

ing entities had sufficient incentive and capital-

ization by the end of the 20th century to con-

duct safety research and development on their

own and about whether such research is more

appropriately conducted at universities.

102

Nonetheless, the renewed commitment to

MSHA’s forced compliance approach at the

apparent expense of the Bureau of Mines’ infor-

mational approach, without closer examina-

tion of the actual effects of the different

approaches,

103

raises the question of whether

the priority of the Congress and President

Clinton was the safety of the nation’s miners or

the appeasement of their special interest con-

stituents.

104

In addition to successfully defeating reform

of the Mine Act, Clinton administration Labor

Department officials actually worked to

expand its reach. Then–secretary of labor Reich

told Congress, “All workers should enjoy the

gains in safety and health achieved for miners

by MSHA and the Mine Act.”

105

In this regard,

it is worth noting that for the last 25 years

MSHA has been expanding its jurisdiction to

workplaces that would not traditionally have

been considered mines.

106

MSHA has even pushed the forced com-

pliance approach beyond the boundaries of

the United States and its territories. On

January 10, 2001, President Clinton signed

the International Labor Organization’s

Convention 176, which is based on the prin-

ciples embodied in the Mine Act.

107

With the

signing, then–secretary of labor Alexis

Herman commented:

Ratification of Convention 176 signals

U.S. commitment to safety and health

protection for workers in one of the

world’s most dangerous occupations. . . .

I would like to commend the Mine Safety

and Health Administration’s former

assistant secretary, Davitt McAteer, the

United Mine Workers of America, and

the National Mining Association for

their work in negotiating Convention

176. . . . Convention 176 reflects that

experience and helps to strengthen labor

standards worldwide.

108

According to McAteer, who visited Ukraine on

MSHA business in 1999, Convention 176 “is

just one aspect of our growing involvement in

international activities.”

109

The Truth about the Mine Act

Before providing all workers in the United

States with Mine Act–type protections and

before pushing the legislative model abroad,

it is fair and necessary to ask whether the

Mine Act has provided a “more effective”

means of preventing death and serious injury

than did the federal policy of no police inter-

vention that preceded it. With all due respect

to McAteer, “the dramatic improvement in

mine safety” is not “proof that the Mine Act

and MSHA are working.” The declining

number of fatalities and the declining fatali-

ty rates provide little, if any, information

about whether MSHA has improved the safe-

ty of miners in the last 25 years.

110

In fact, it is disingenuous for MSHA to

claim success on the basis of the favorable

trends in mine safety

111

because, as Figure 1

clearly shows, the trends did not begin in

1977 with the enactment of the Mine Act or

even in 1969 with the enactment of the Coal

Act. The fact that mining fatalities, in

absolute numbers, or even on a rated basis,

have continued to decline after federal inter-

11

It is disingenuous

for MSHA to

claim success on

the basis of the

favorable trends

in mine safety

because the

trends did not

begin in 1977

with the enact-

ment of the Mine

Act or even in

1969 with the

enactment of the

Coal Act.

vention does not establish that forced com-

pliance contributed to the decline.

Even assuming that the trend toward

safer mines accelerated after 1969 or after

1977, there would still be questions about

causation because a correlation, by itself,

does not establish cause and effect. For exam-

ple, using the Labor Department’s simplistic

reasoning, it could be argued that MSHA’s

forced compliance model, which was expand-

ed in 1977, has been extraordinarily effective

at eliminating mining jobs in the United

States (Figure 3).

Although the creation of MSHA coincides

with the loss of 30 percent of all U.S. mining

jobs in the last 25 years, that correlation, by

itself, does not prove that the Mine Act elimi-

nated mining jobs. Thus, without the benefit

of a statistical analysis that establishes that the

trend toward safer mines accelerated after pas-

sage of the acts and without a tested theory of

causation, MSHA’s claims are pure puffery.

112

There is one 1980 study that at first glance

appears to support some of MSHA’s self-

aggrandizing conclusions.113 Professors

Michael Lewis-Beck and John Alford conclud-

ed, on the basis of a multiple interrupted time

series (MITS) statistical analysis, that “the

1941 and 1969 federal safety legislation

appears to have diminished significantly the

risk of receiving a fatal injury while mining

coal.”114 To a certain extent, the time series

data, which they developed, statistically quan-

tify the declines in fatalities per number of

coal miners after 1969 that can be observed

using MSHA’s data (Figures 4 and 5).

In addition to attributing statistical sig-

nificance to the downward slope in coal min-

ing fatality rates after 1969, the professors

further concluded that the observable

decline was attributable to “regulatory influ-

ences” and not changes in mine size, technol-

ogy, or the type of mining.

115

While the Lewis-Beck and Alford study is

certainly a step in the right direction in terms

of attempting to determine whether forced

compliance influenced the trend toward fewer

mine fatalities, it is by no means the end of the

story. In this respect, their ultimate conclu-

sion, that “it is possible for Congress to enact

12

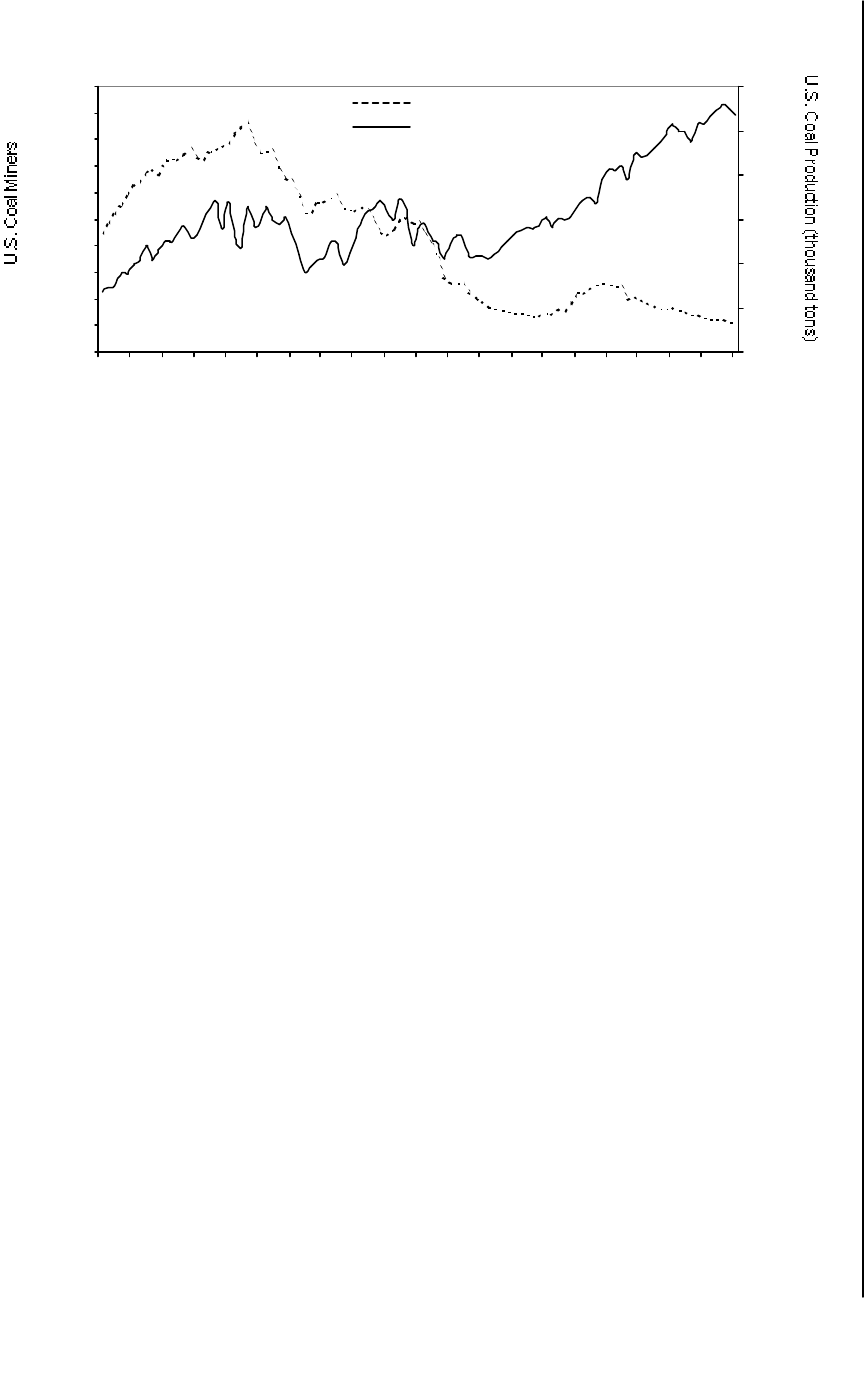

Figure 3

The Loss of U.S. Mining Jobs after Enactment of the Mine Act

Sources: Author’s calculation (metal/nonmetal miners + coal miners) based on data from U.S. Department of

Labor, MSHA Internet, Metal/Nonmetal Fatalities 1900 [1931] through 2001, www.msha.gov/centurystats/mnm

stats.htm; and U.S. Department of Labor, MSHA Internet, Coal Fatalities for 1900 through 2001, www.msha.gov/

centurystats/coalstats.htm.

350,000

400,000

450,000

500,000

550,000

600,000

1977 1979 1981 1983 1985 1987 1989 1991 1993 1995 1997 1999 2001

Year

Even assuming

that the trend

toward safer

mines accelerated

after 1969 or after

1977, there would

still be questions

about causation

because a correla-

tion, by itself,

does not establish

cause and effect.

13

Figure 4

U.S. Coal Mining Fatalities per 100,000 Miners

Source: Author’s calculation ([fatalities ÷ number of miners] × 100,000) based on data from U.S. Department of

Labor, MSHA Internet, Coal Fatalities for 1900 through 2001, www.msha.gov/centurystats/coalstats.htm (sand and

gravel workers included beginning in 1958, office workers in 1973).

Figure 5

U.S. Metal/Nonmetal Mining Fatalities per 100,000 Miners

Source: Author’s calculation ([fatalities ÷ number of miners] × 100,000) based on data from U.S. Department of

Labor, MSHA Internet, Metal/Nonmetal Fatalities 1900 [1911] through 2001, www.msha.gov/centurystats/mnm

stats.htm (sand and gravel workers included beginning in 1958, office workers in 1973).

0

100

200

300

400

500

600

1900

1905

1910

1915

1920

1925

1930

1935

1940

1945

1950

1955

1960

1965

1970

1975

1980

1985

1990

1995

2000

Year

0

20

40

60

80

100

120

140

160

180

200

1931

1935

1939

1943

1947

1951

1955

1959

1963

1967

1971

1975

1979

1983

1987

1991

1995

1999

Year

laws that successfully regulate American busi-

ness for some public purpose, such as safer

coal mines,”

116

sounds more political than

analytical or factual. Although their analysis

may be more glamorous than the numbers

that MSHA tosses around on Capitol Hill, it is

no more compelling for at least a half dozen

reasons.

First, as is the case in any time series analy-

sis, the study, by selecting independent vari-

ables, arbitrarily defines the data set. Lewis-

Beck and Alford selected 1941, 1952, and

1969 because federal legislation affecting

mine safety was enacted in those years. The

particular problem with that approach is

that Lewis-Beck and Alford neglected to

include the 1910 creation of the Bureau of

Mines. Their exclusion of the 1910 legisla-

tion is totally inconsistent with their inclu-

sion of the 1941 legislation, which allowed

the federal government to make recommen-

dations to mine operators, because it is iden-

tical in principle to the approach taken by the

federal government in 1910. By erroneously

treating the Mine Inspection Act of 1941 as

“the ‘first’ law” affecting the mining indus-

try,

117

the study ignores the important and

continuing contribution of the Bureau of

Mines that began in 1910, thereby exaggerat-

ing the purported observed effects of the

other laws.

Second, the more general problem with

preselecting variables is that it imposes pre-

conceived ideas on the data instead of allow-

ing the graphic representation of the data to

suggest areas of inquiry. At least with respect

to safety issues, the starting point should be

to identify statistically meaningful trends

and then to work backwards, hypothesizing

about the factors that may have contributed

to the trends. In that regard, eyeballing

Lewis-Beck and Alford’s man-hour data

points suggests that the steep downward

trend, which they attribute to the 1969 act,

actually began 10 years earlier in 1960, which

incidentally coincides with the introduction

of the roof-bolting machine to underground

coal mining.

118

Although the MITS approach

might be useful in supporting a preconceived

idea (to the extent that the data cooperate), it

is not especially appropriate in a field where

proper identification of causes and effects

can be a matter of life and death.

Third, the Lewis-Beck and Alford study

relies on a simplistic data set. While the use of

conglomerated data is certainly convenient

and possibly appropriate to show general

trends, it does not have as much explanatory

power as the unconglomerated data.

119

Inside

the Bureau of Mines’ data set are potential

subsets of data: surface versus underground,

bituminous versus anthracite, western versus

eastern, large mine versus small mine, state

versus state, and even union versus nonunion.

Each subset may tell a different story about

the effects of federal legislation. In addition,

because they looked at only the national

trends, Lewis-Beck and Alford made no

attempt to differentiate between mining disas-

ters and normal-course-of-work fatalities. A

large disaster, such as Farmington where 78

miners died in a single accident, can distort

short-term and long-term trends, such as the

downward trend in coal mine fatalities that

appears to have begun in the early 1960s.

Fourth, Lewis-Beck and Alford greatly exag-

gerate the utility of MITS analysis in making

cause and effect determinations. They conclude

that “beyond doubt, the harsher provisions of

the 1969 Act have made the coal mines safer.”

120

However, of the ”numerous” variables that

might affect mine safety, their study attempts

to account for only three, for which they “man-

aged to assemble satisfactory data.”

121

Lewis-

Beck and Alford considered only mine size,

mining technology, and type of mining. There

are numerous other possible macro explana-

tions that might account for the favorable

trends in coal mining fatalities, including, but

not limited to, the replacement of tort liability

with workers’ compensation, the subsequent

reform of workers’ compensation, the develop-

ment of third-party and product liability doc-

trines, the standard of living, the proliferation

of mass media communications, the mass con-

sumption of automobiles, the build-out of the

medical infrastructure, and even U.S. participa-

tion in foreign wars. They also did not evaluate

14

The steep down-

ward trend in

fatalities coin-

cides with the

introduction of

the roof-bolting

machine to

underground coal

mining.

numerous potential mining-specific explana-

tions for the favorable trends in fatalities,

including, but not limited to, the price of coal,

national demand for coal, the nature of the

mining labor force,

122

the consolidation of

mine operators, state mining laws, and geo-

graphic mining activity. As the study concedes,

those other unaccounted-for variables might

“contribute significantly to an explanation of

mine safety.”

123

Fifth, with regard to the variables that

Lewis-Beck and Alford attempted to take into

account (mine size, mining technology, and

type of mining), it is not altogether clear that

simply treating them as “third variables” ade-

quately captures the extent of their effect on

mine safety.

124

Moreover, the indicators that

they selected to represent those variables are

also questionable. For example, using produc-

tivity as the sole indicator of advances in min-

ing technology would not capture technologi-

cal innovations that substantially enhance

safety without significantly affecting produc-

tion, such as the proliferation of permissible

explosives, permissible equipment, rock-dust-

ing applicators, self-rescuers, rollover protec-

tion, fire alarm and suppression systems, ven-

tilation techniques, and roof bolting. In addi-

tion, to the extent that the federal legislation

may be responsible for declines in productivi-

ty, the full effect of non-safety-specific innova-

tions might actually be hidden by their “third

variable” approach.

There Is No Evidence That

the Mine Act Has Effectively

Reduced Fatalities

The sixth and most important reason that

the Lewis-Beck and Alford study does not

withstand scrutiny is that it relies on an infe-

rior measure of mine safety progress. A com-

parison of (1) annual fatalities per 100,000

miners, which is MSHA’s version of Lewis-

Beck and Alford’s annual fatalities per mil-

lion man-hours,

125

and (2) annual fatalities

per million tons mined shows discrepant

trends.

One interpretation of the discrepancy,

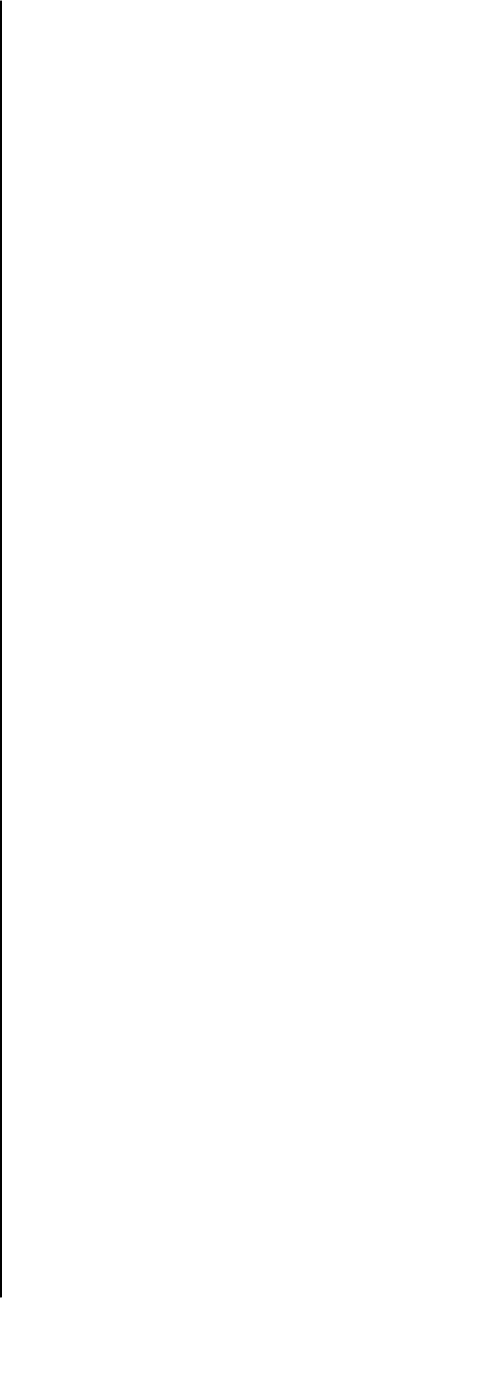

which appears in Figure 6, is that fatality rates

per miner and, by extension, rates per man-

hour,

126

do not accurately represent the favor-

able trend in mine safety improvement.

The fatalities per million tons rate, which

shows a near continuous downward trend, is a

superior measure of mine safety. Fatality rates

based on tonnage are superior to fatality rates

based on miners or man-hours because they

reflect changing exposure to mine hazards

more accurately. Although a man-hour rate

reflects exposure somewhat better than does

the number of employees, a man-hour rate

does not adequately capture a miner’s expo-

sure to hazards because it assumes that the

pace of mining per hour is constant over time.

The reality is that miners move more ground

in one hour today than they did in 1900.

127

It

is generally accepted that the more ground is

moved, the more hazards will be encoun-

tered.

128

For that reason, the fatalities per mil-

lion tons rate, which better captures the haz-

ards encountered during mining, is a better

means of assessing safety progress within the

coal mining industry.

129

Fatalities per million tons is a superior

measure of intraindustry safety progress from

a public policy perspective as well.

130

It direct-

ly correlates coal output, which public policy

aims to maximize, and fatalities, which public

policy aims to minimize. By directly compar-

ing the two most relevant variables, the possi-

bility of a false safety gain is eliminated. When

using fatalities per million man-hours,

changes in productivity can conceal changes

in safety. A decline in productivity, resulting

from more miners mining less coal, can make

the mines appear safer even when fatalities in

the more dangerous mining occupations do

not decline in absolute numbers. For example,

adding miners to do nonproduction work,

such as liaising with MSHA inspectors or fill-

ing out paperwork, away from the face of an

underground coal mine can lower fatality

rates per man-hour or per miner without low-

ering the fatality rate per ton.

131

In this connection, Labor Department

employee Hal Sider, in an unheralded but

15

A comparison of

annual fatalities

per 100,000 min-

ers and annual

fatalities per mil-

lion tons mined

shows discrepant

trends.

important statistical analysis,

132

found that the

“spectacular decline in productivity during the

1970s” was not the result of improvements in

safety conditions but rather the result of a sim-

ple decline in the production of marketable

output.

133

The converse and corollary implica-

tion of Sider’s analysis is that the productivity

declines that followed the 1969 Coal Act

134

may

also explain the improvement in the fatality per

man-hour rate observed by Lewis-Beck and

Alford.

135

In other words, the improvement in

fatalities per million man-hour data that fol-

lowed the 1969 Coal Act might actually reflect

a decrease in exposure to hazards resulting

from each employee mining less coal and not

from a genuine improvement in mine safety.

The clear implication of Sider’s analysis is that

the beneficial safety effects of the Coal Act

observed by Lewis-Beck and Alford are illusory.

In sum, while the man-hour and employee

rates may be useful for comparing mining

with other industries and for informing min-

ers about the relative risks that they face com-

pared with workers in other industries, the per

ton rate is superior as an intraindustry mea-

sure of safety progress. For example, the per

million ton measure is used to compare the

safety of mines in different countries whose

productivity rates may vary considerably.

136

Although MSHA does not use the measure on

a regular basis, the agency has used it when it

helps make a point.

137

Figure 7 isolates and

enlarges the fatalities per million tons trend

set out above in Figure 6.

The implications of Figure 7 are profound.

It appears that the federal government inter-

vened at a point when safety gains on a per mil-

lion ton basis were already declining at a rapid

rate. Moreover, unfavorable changes in the

trend that coincide with federal intervention

raise serious questions about whether forced

compliance may actually have even been detri-

16

The improvement

in fatalities per

million man-hour

data that followed

the 1969 Coal Act

might actually

reflect a decrease

in exposure to

hazards resulting

from each

employee mining

less coal and not

from a genuine

improvement in

mine safety.

Figure 6

Divergent U.S. Coal Mining Fatality Rates

0

1

2

3

4

5

6

7

8

1900

1910

1920

1930

1940

1950

1960

1970

1980

1990

2000

0

100

200

300

400

500

600

Per Ton

Per Miner

Sources: Fatalities per ton, author’s calculation (fatalities ÷ tons ×

1000) based on data from U.S. Department of

Labor, MSHA Internet, Coal Fatalities for 1900 through 2001 www.msha.gov/centurystats/coalstats.htm; Energy

Information Administration, Coal Products Publications, Coal Data: A Reference, Table 18, U.S. Production Trends

in Bituminous Coal and Lignite, 1900–1993 (total production, thousand short tons), 1995, pp. 65–66,

http://tonto.eia.doe.gov/FTPROOT/coal/006493.pdf; Pennsylvania Department of Environmental Protection,

Mining and Reclamation, 2000 Annual Report on Mining Activities, Table 1: Anthracite Statistical Summaries

1870 to 2000 (production, net tons, converted to thousand tons), www.dep.state.pa.us/dep/deputate/minres/bmr/

annualreport/2000/table_01.htm; and Energy Information Administration, Coal Products Publications, Coal

Industry Annuals 1994–2000 (thousand short tons), http://tonto.eia.doe.gov/FTPROOT/coal/coalpubs.htm.

Fatalities per miner, author’s calculation ([fatalities ÷ number of miners] ×

100,000) based on data from U.S.

Department of Labor, MSHA Internet, Coal Fatalities for 1900 through 2001, www.msha.gov/centurystats/coal

stats.htm

Year

mental to mine safety.

138

An MITS analysis of

the data, akin to Lewis-Beck and Alford’s study,

would almost certainly show that each succes-

sive stage of increasing federal intervention,

especially after 1941, progressively slowed the

trend toward safer coal mines. Thus, it is entire-

ly possible that the federal government not only

got to the safety-improvement celebration late

but may also have broken up the party.

The Reasons Forced

Compliance Does Not

Protect Miners

Alleging that federal intervention has been

detrimental to mine safety is considered

heresy even by critics of the forced compliance

model, who at least pay homage to the historic

role that forced compliance has played in

bringing mine safety to where it is today.

139

In

addition, attempting to establish that the

Mine Act has stalled the trend toward fewer

mine fatalities presents the same statistical

and causation hurdles that proponents of the

enforcement model have conveniently ignored

in touting the lifesaving benefits of the Mine

Act. Nonetheless, a comparison of the forced

compliance and market models suggests that

it is entirely possible that Congress may have

actually done more harm than good with the

Coal and Mine Acts. Each of the three compo-

nent parts of the forced compliance approach

is inferior to the equivalent feature of the mar-

ket-based approach that it tried to replace and,

more important, may impair the effectiveness

of the market-based counterparts.

The Substitution of Rules for Results

In the market-based approach to mine

safety there are no restrictions on the means

by which mine operators achieve reductions in

17

It is entirely pos-

sible that the fed-

eral government

not only got to

the safety-

improvement

celebration late

but may also have

broken up the

party.

0

1

2

3

4

5

6

7

8

1900

1905

1910

1915

1920

1925

1930

1935

1940

1945

1950

1955

1960

1965

1970

1975

1980

1985

1990

1995

2000

Figure 7

Behind the Curve: Increased Intervention by the U.S. Government in Mine Safety

May Have Decreased the Rate of Decline in Coal Fatality Rates

Sources: Author’s calculation (fatalities ÷ tons × 1000) based on data from U.S. Department of Labor, MSHA

Internet, Coal Fatalities for 1900 through 2001, www.msha.gov/centurystats/coalstats.htm; Energy Information

Administration, Coal Products Publications, Coal Data: A Reference, Table 18, U.S. Production Trends in

Bituminous Coal and Lignite, 1900–1993 (total production, thousand short tons), 1995, pp. 65–66, http://tonto.

eia.doe.gov/FTPROOT/coal/006493.pdf; Pennsylvania Department of Environmental Protection, Mining and

Reclamation, 2000 Annual Report on Mining Activities, Table 1: Anthracite Statistical Summaries 1870 to 2000

(production, net tons, converted to thousand tons), www.dep.state.pa.us/dep/deputate/minres/bmr/annual

report/2000/table_01.htm; and Energy Information Administration, Coal Products Publications, Coal Industry

Annuals 1994–2000 (thousand short tons), http://tonto.eia.doe.gov/FTPROOT/coal/coalpubs.htm.

Fatalities per Million Tons of Coal

Year

1910: BOM Disseminates Information

1941: BOM Makes Recommendations

1952: BOM Issues Second Instance Violations

1969: BOM/MESA Issues First Instance Violations

1977: MSHA Issues First Instance Violations with Stiffer Penalties

injuries. Mine operators are free to use

employee bonuses, engineering controls,

behavior-based programs, or whatever else

works to bring down injury rates. In contrast,

the forced compliance model depends entirely

on the administration and enforcement of

regulations to reduce accidents. There are

numerous shortcomings inherent in the regu-

latory approach.

First, it has never been established that

regulation of mining operations prevents

accidents. Conventional wisdom holds:

The risks regulated by these two agen-

cies are well understood. We know we

need regulations on ladders, slippery

floors, lighting, and similar matters in

order to protect workers. We know from

experience that these agencies’ regula-

tions prevent deaths. We do not want to

meddle with success.

140

However, even scholarly proponents of forced

compliance have conceded the possibility that

safety regulations might not have any positive

impact on accident rates.

141

As set out above, a

preliminary look at the fatalities per million

tons data suggests that forced compliance

might have actually slowed the trend toward

fewer fatal injuries at coal mines.

142

Regardless of whether any accidents can be

prevented with regulations, it is clear that all

accidents cannot be eliminated through regula-

tion. One occupational safety and health schol-

ar has noted that even in less dynamic OSHA-

regulated environments, “most workplace

injuries are not caused by violations of stan-

dards, and even fewer are caused by violations

that inspectors can detect.”

143

There have been

fatalities at mining operations where even

MSHA, which strives to cite a violation in every

fatality case,

144

has conceded that there was no

violation of the regulations.

145

It is simply

impossible to address all conceivable hazardous

conditions and practices through regulation.

In response to the fact that it is impossible

to regulate every conceivable hazard at min-

ing operations, many of MSHA’s regulations

are deliberately vague with respect to the spe-

cific conditions or practices that are required

or prohibited. For example, many of the

metal/nonmetal regulations simply instruct

mine operators to be “safe” and to avoid

practices or conditions that may create a

“hazard” or be “dangerous.”

146

Although it

has been held by the courts that such “per-

formance” regulations meet the minimum

requirements of due process

147

and although

such “performance” regulations do afford

the mine operator flexibility in achieving

compliance,

148

the reality is that such regula-

tions provide no meaningful guidance to

mine operators about what conditions may

be hazardous or how to eliminate them.

While such regulations are ideal for 20/20

hindsight enforcement, they are worthless as

guidelines for the prevention of accidents.

149

The regulations that are specific enough to

provide guidance to mine operators are often

too prescriptive. Many MSHA regulations,

particularly ones governing coal mining, are

so specific that they discourage innovation.

150

Mine operators are generally reluctant to

implement high- or even low-tech safety inno-

vations because doing so, in many instances,

requires the mine operator to petition MSHA

for a variance.

151

Under MSHA’s regulations,

such variances, even if granted on the first go

around, take a minimum of 60 days.

152

It often

takes many months or sometimes even years

to get a variance.

153

In some instances, where

the mine operator cannot convincingly per-

suade an Arlington, Virginia, bureaucrat that

its innovative approach will not diminish safe-

ty in any way, variances are not granted at

all.

154

The limitations of such a system in an

industry in which conditions change hourly

are obvious. Indeed, all but the most ardent

advocates of regulation have conceded that

regulations do not induce innovation.

155

Perhaps the biggest failing of MSHA’s regu-

lations is their relentless focus on the “unsafe

condition and unsafe act” approach to mine

safety to the detriment of other more innova-

tive approaches. Almost all of MSHA’s regula-

tions address workplace conditions. While

there are a few regulations that prohibit unsafe

actions, they have not been particularly effective

18

It has never been

established that

regulation of

mining opera-

tions prevents

accidents.

at changing behavior.

156

In this connection,

modern accident prevention theory, which

focuses on behavior-based approaches to

improving safety, has passed by MSHA’s regu-

latory approach, which remains firmly rooted

in the “unsafe-act/unsafe-condition” theory

developed in the first third of the 20th centu-

ry.

157

Although MSHA regulations do not pre-

clude mine operators from implementing

behavior-based safety programs, the perception

in the industry is that MSHA, whose focus is on

assigning blame to the mine operator and pro-

tecting employee rights, is not receptive to

behavior-based approaches.

158

Moreover, small-

er mining operations, which often do not have

the resources to implement two types of safety

programs, are forced to focus their available

resources on a safety program that is geared

toward regulatory compliance.

159

The Substitution of Inspector Vigilance

for Employee Vigilance

The keystone of the market-based approach

to mine safety is the strong incentive that an

individual miner has to provide for his own

safety and well-being. In contrast, the regulato-

ry approach to safety embodied in the Mine

Act, which essentially creates a miner’s entitle-

ment to a safe workplace, largely exempts min-

ers from responsibility for their own and others’

safety. Instead, the Mine Act approach relies pri-

marily on periodic, mandatory inspections con-

ducted by federal mine inspectors to enforce

compliance with the regulations. The forced

compliance approach is inferior to the market

approach, not only because inspectors are inca-

pable of doing a better job than miners at

ensuring a safe workplace, but also because

forced compliance creates a moral hazard for

the miners.

Although the 1977 Congress recognized

that the individual miner had an essential role

even in the forced compliance approach to

mine safety,

160

the Mine Act placed the entire

responsibility for safety on the mine operator.

The 1977 Congress explained:

Thus, while miners are required to com-

ply with standards insofar as they are

applicable to their own actions and con-

duct, except with respect to the penalty

for smoking in a mine, (Section 111(i)),

neither the bill, nor current law contem-

plates that citations and penalties be

issued against miners. Operators have

the final responsibilities for affording

safe and healthful workplaces for miners,

and therefore, have the responsibility for

developing and enforcing through

appropriate disciplinary measures, effec-

tive safety programs that could prevent

employees from engaging in unsafe and

unhealthful activity.

161

Thus, even though the Mine Act pays lip service

to the important role of miners,

162

the act

exempts the individual miner from any civil or

criminal liability, with the one exception related

to smoking, regardless of whether he puts him-