FY 2020

CONGRESSIONAL BUDGET JUSTIFICATION

MINE SAFETY AND HEALTH ADMINISTRATION

This page is intentionally left blank.

MINE SAFETY AND HEALTH ADMINISTRATION

TABLE OF CONTENTS

Appropriation Language ..................................................................................................... 1

Amounts Available for Obligation...................................................................................... 2

Summary of Changes .......................................................................................................... 3

Summary Budget Authority and FTE by Activity .............................................................. 5

Budget Authority by Object Class ...................................................................................... 7

Authorizing Statutes............................................................................................................ 8

Appropriation History ......................................................................................................... 9

Overview ........................................................................................................................... 10

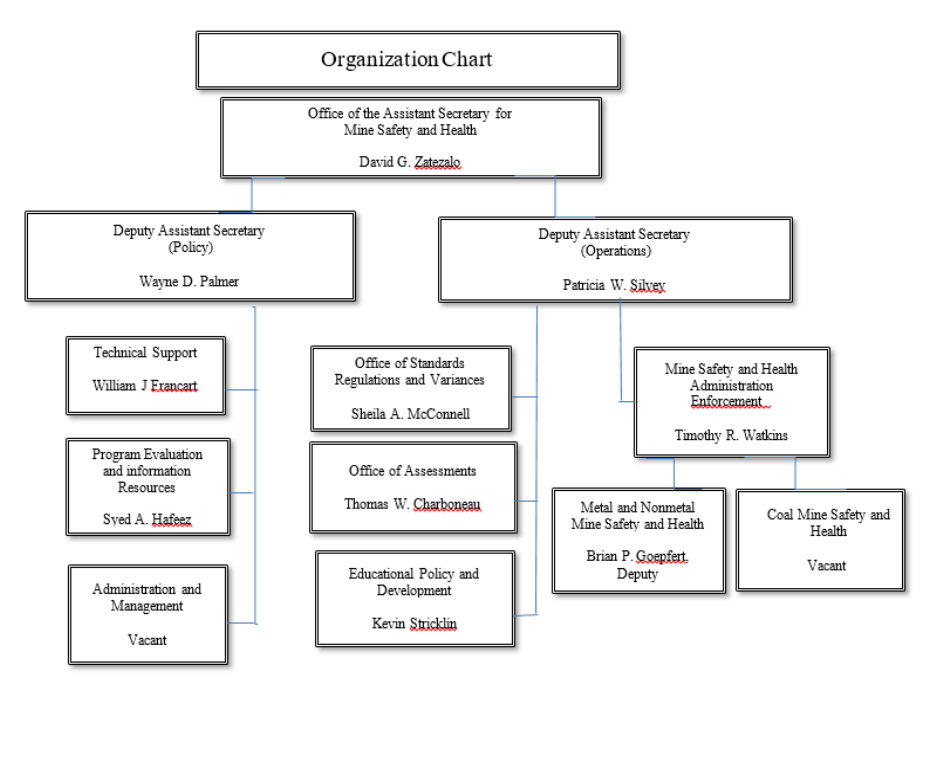

Organization Chart ............................................................................................................ 13

Budget Activities .............................................................................................................. 15

Mine Safety and Health Enforcement ........................................................................... 15

Coal Mine Safety and Health ........................................................................................ 23

Metal and NonMetal Mine Safety and Health .............................................................. 31

Office of Standards, Regulations, and Variances ......................................................... 39

Office of Assessments................................................................................................... 45

Educational Policy and Development ........................................................................... 51

Technical Support ......................................................................................................... 57

Program Evaluation and Information Resources .......................................................... 65

Program Administration................................................................................................ 71

This page is intentionally left blank.

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 1

APPROPRIATION LANGUAGE

SALARIES AND EXPENSES

For necessary expenses for the Mine Safety and Health Administration, [$373,816,000]

$376,043,000, including purchase and bestowal of certificates and trophies in connection with mine

rescue and first-aid work, and the hire of passenger motor vehicles, including up to $2,000,000 for

mine rescue and recovery activities and not less than $10,537,000 for State assistance grants:

Provided, That amounts available for State assistance grants may be used for the purchase and

maintenance of new equipment required by the final rule entitled "Lowering Miners' Exposure to

Respirable Coal Mine Dust, Including Continuous Personal Dust Monitors" published by the

Department of Labor in the Federal Register on May 1, 2014 (79 Fed. Reg. 24813 et seq.), for

operators that demonstrate financial need as determined by the Secretary: Provided further, That

notwithstanding 31 U.S.C. 3302, not to exceed $750,000 may be collected by the National Mine

Health and Safety Academy for room, board, tuition, and the sale of training materials, otherwise

authorized by law to be collected, to be available for mine safety and health education and training

activities: Provided further, That notwithstanding 31 U.S.C. 3302, the Mine Safety and Health

Administration is authorized to collect and retain up to $2,499,000 from fees collected for the

approval and certification of equipment, materials, and explosives for use in mines, and may utilize

such sums for such activities: Provided further, That the Secretary is authorized to accept lands,

buildings, equipment, and other contributions from public and private sources and to prosecute

projects in cooperation with other agencies, Federal, State, or private: Provided further, That the Mine

Safety and Health Administration is authorized to promote health and safety education and training in

the mining community through cooperative programs with States, industry, and safety associations:

Provided further, That the Secretary is authorized to recognize the Joseph A. Holmes Safety

Association as a principal safety association and, notwithstanding any other provision of law, may

provide funds and, with or without reimbursement, personnel, including service of Mine Safety and

Health Administration officials as officers in local chapters or in the national organization: Provided

further, That any funds available to the Department of Labor may be used, with the approval of the

Secretary, to provide for the costs of mine rescue and survival operations in the event of a major

disaster. (Department of Labor Appropriations Act, 2019.)

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 2

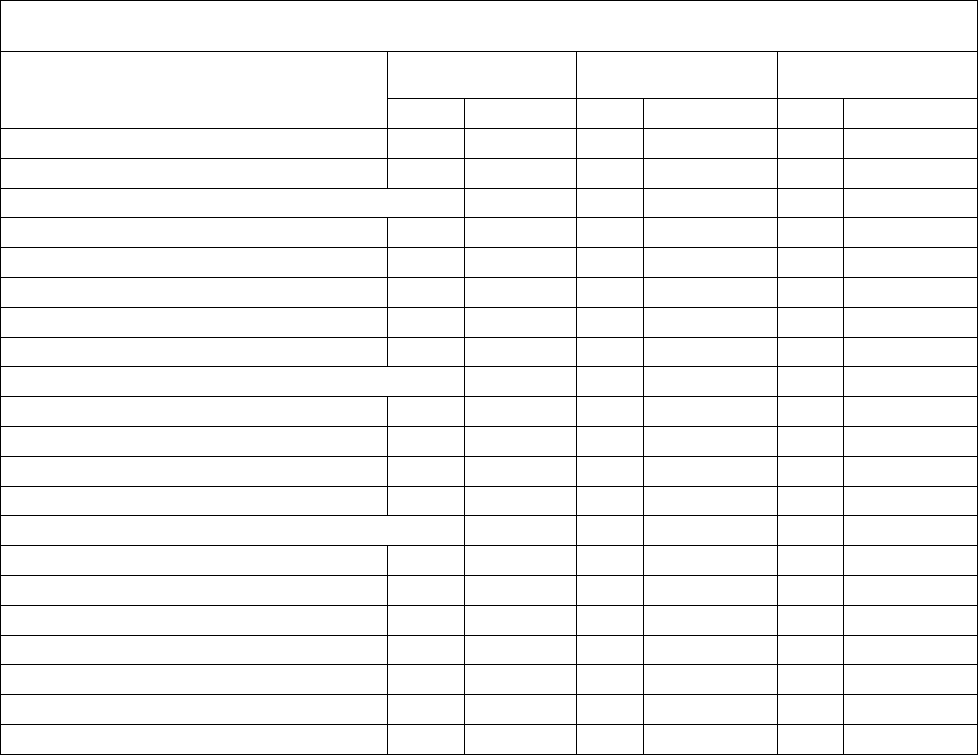

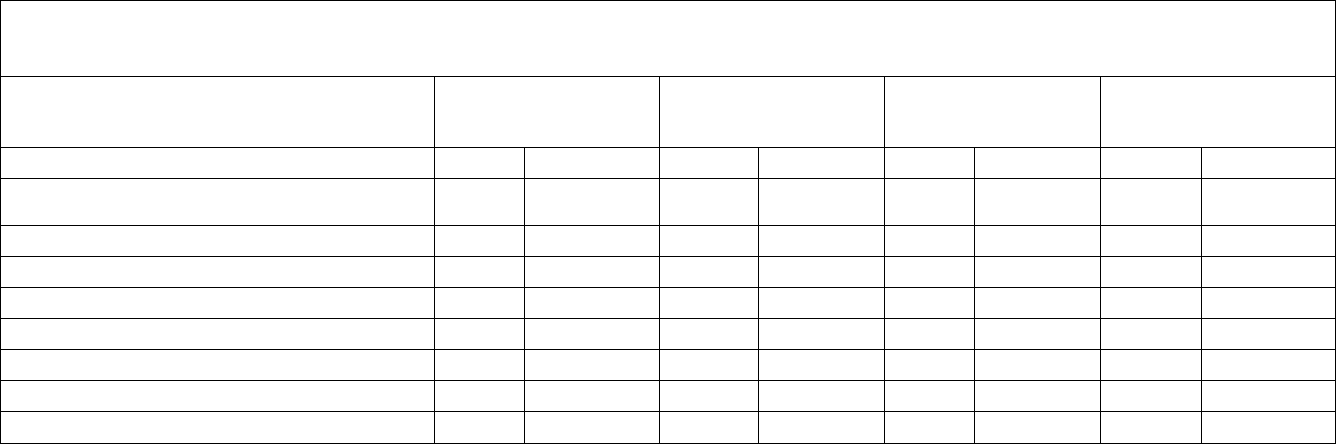

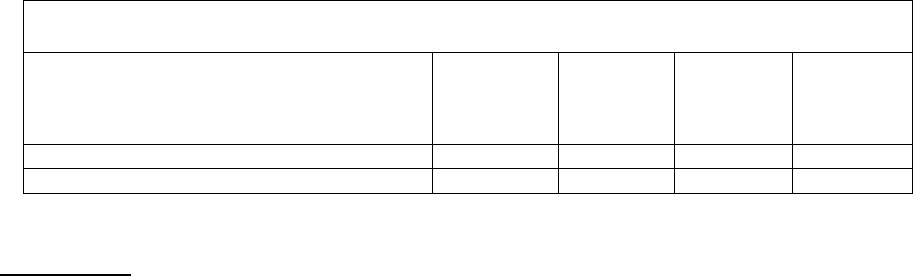

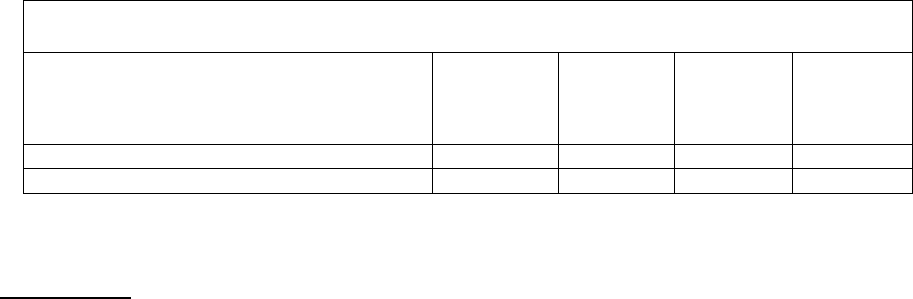

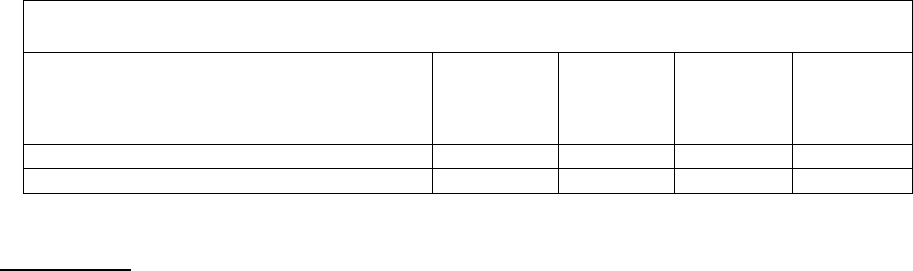

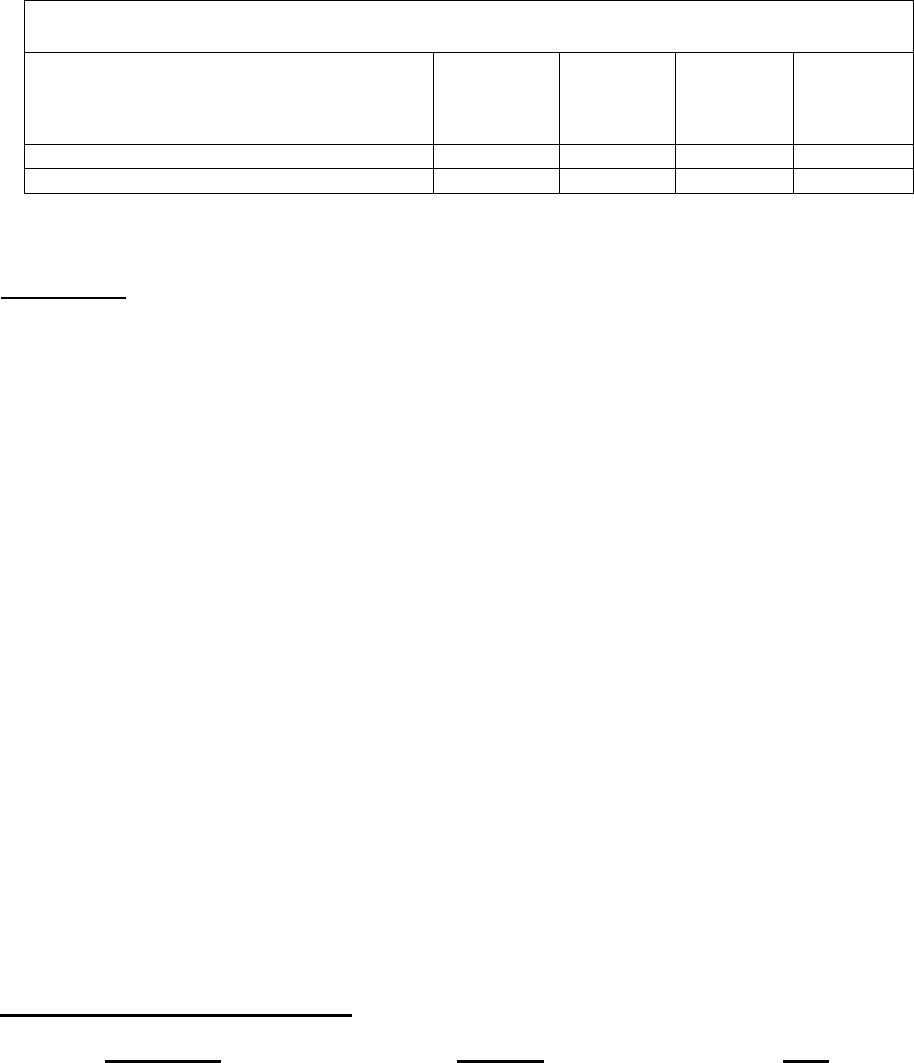

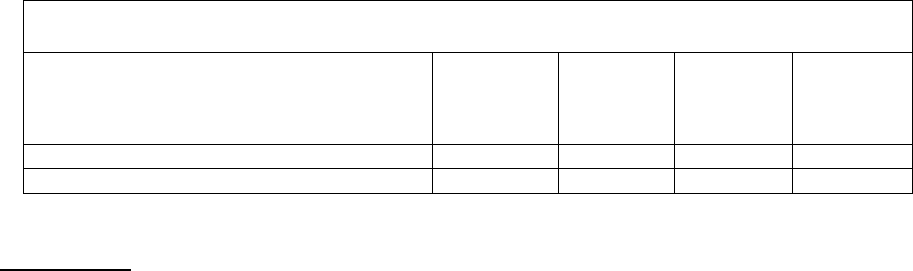

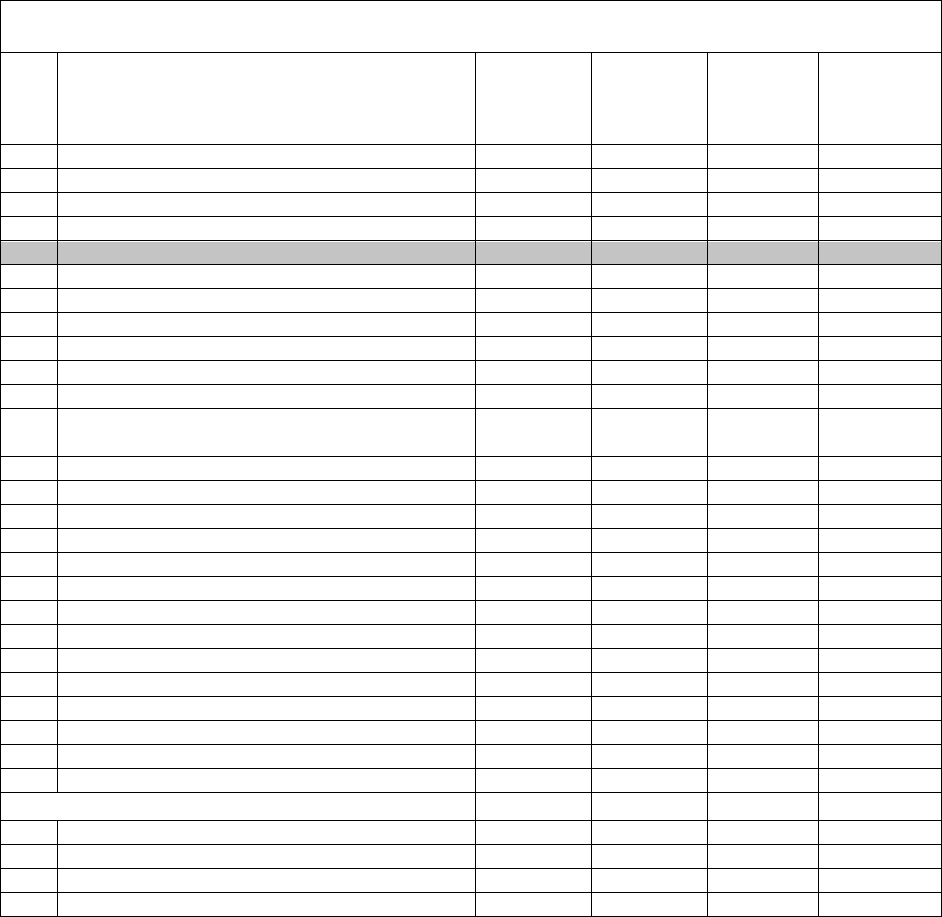

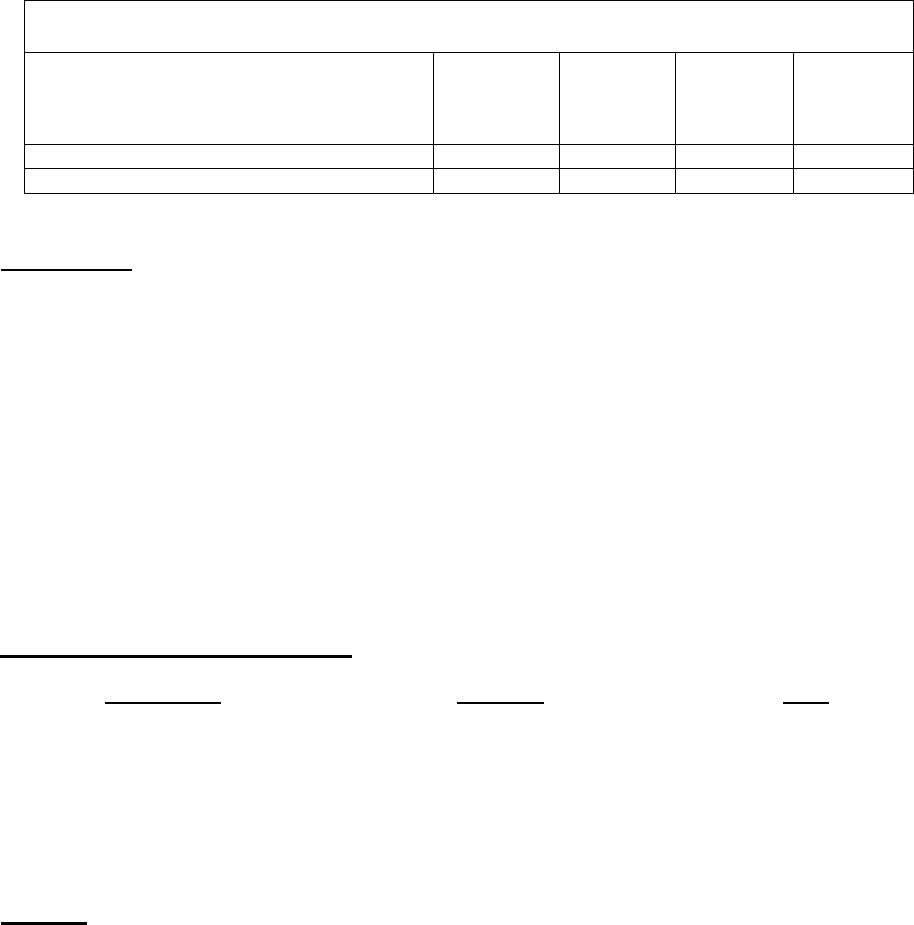

AMOUNTS AVAILABLE FOR OBLIGATION

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

FTE

Amount

FTE

Amount

FTE

Amount

A. Appropriation

2,053

$373,816

1,984

$373,816

1,984

$376,043

Offsetting Collections From:

Reimbursements

0

$3,249

0

$3,249

0

$3,249

Subtotal

2,053

$377,065

1,984

$377,065

1,984

$379,292

B. Gross Budget Authority

2,053 $377,065 1,984 $377,065 1,984 $379,292

IT Consolidation

0

$0

0

$0

0

$0

Offsetting Collections to:

Reimbursements

0

-$3,249

0

-$3,249

0

-$3,249

Subtotal

2,053

$373,816

1,984

$373,816

1,984

$376,043

C. Budget Authority Before Committee

2,053

$373,816

1,984

$373,816

1,984

$376,043

Offsetting Collections From:

Reimbursements

0

$1,409

0

$3,249

0

$3,249

Subtotal

2,053

$375,225

1,984

$377,065

1,984

$379,292

D. Total Budgetary Resources

2,053 $375,225 1,984 $377,065 1,984 $379,292

Unobligated Balance Expiring

-60

-$760

0

$0

0

$0

E. Total, Estimated Obligations

1,993

$374,465

1,984

$377,065

1,984

$379,292

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 3

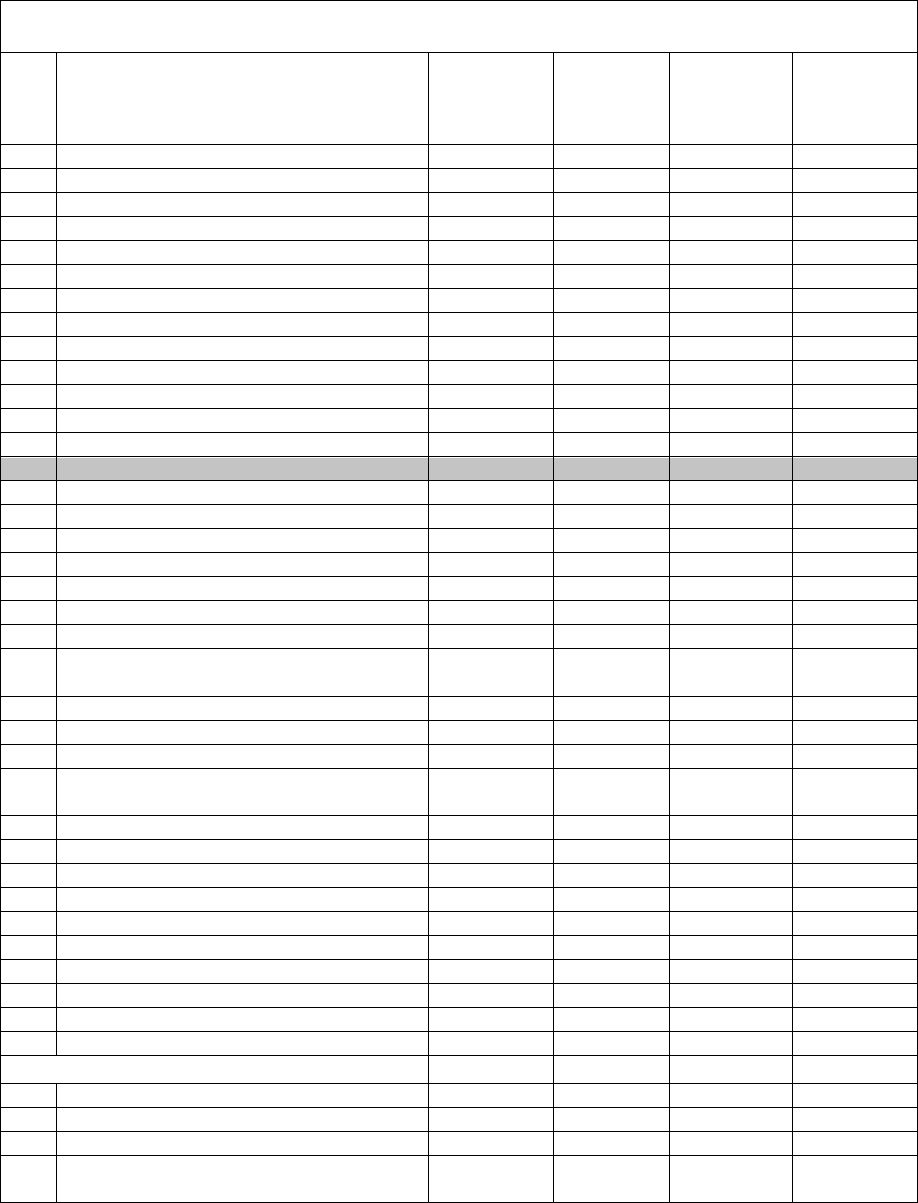

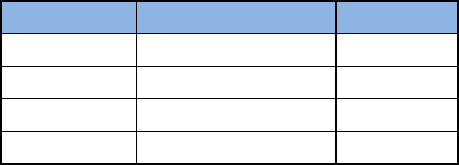

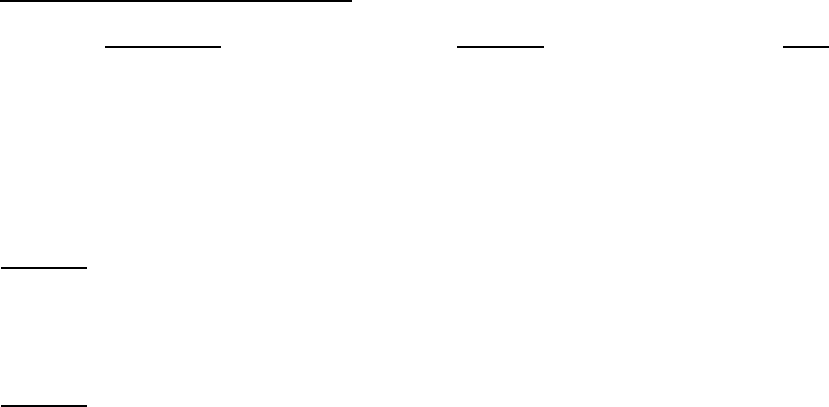

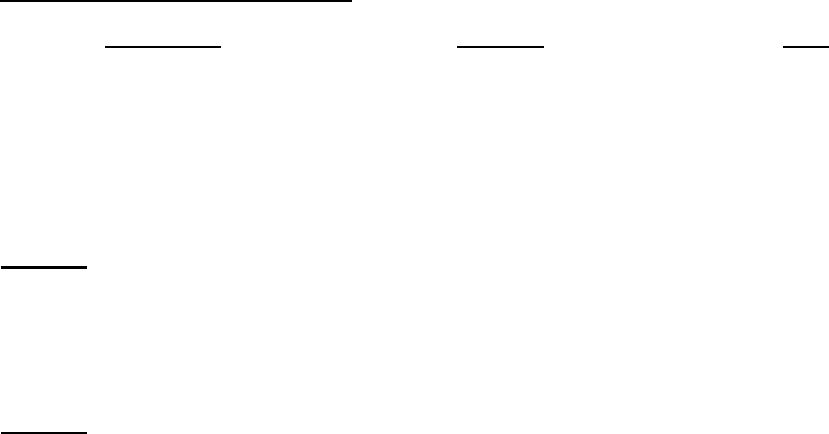

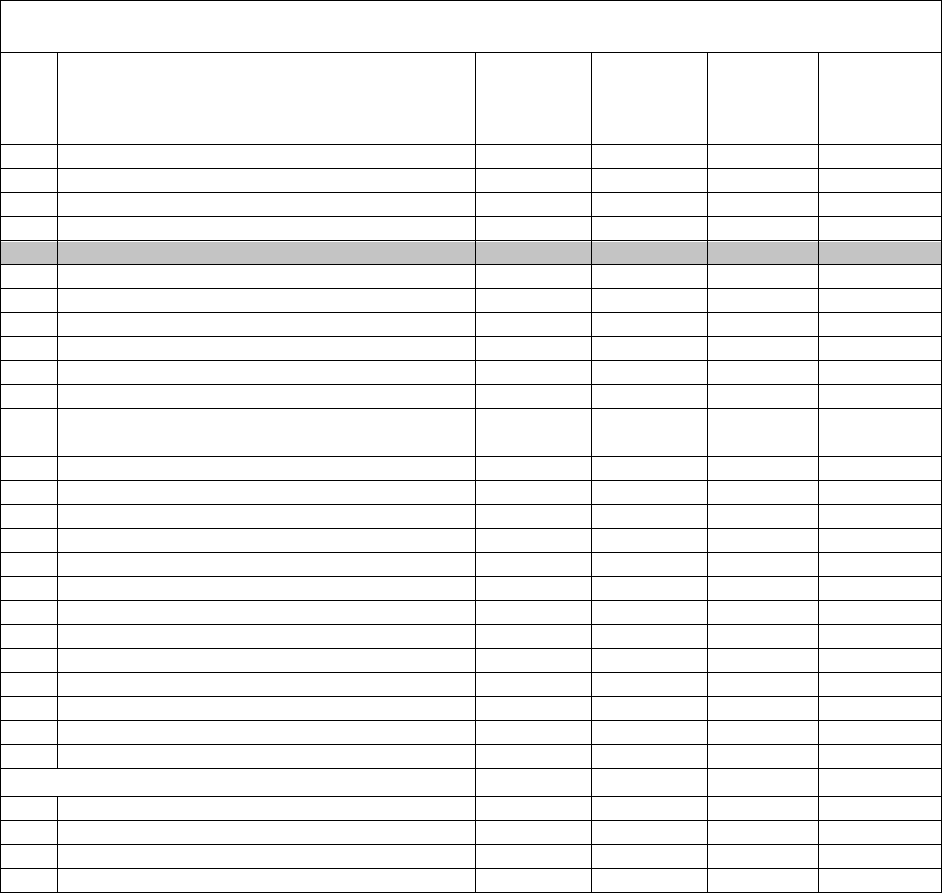

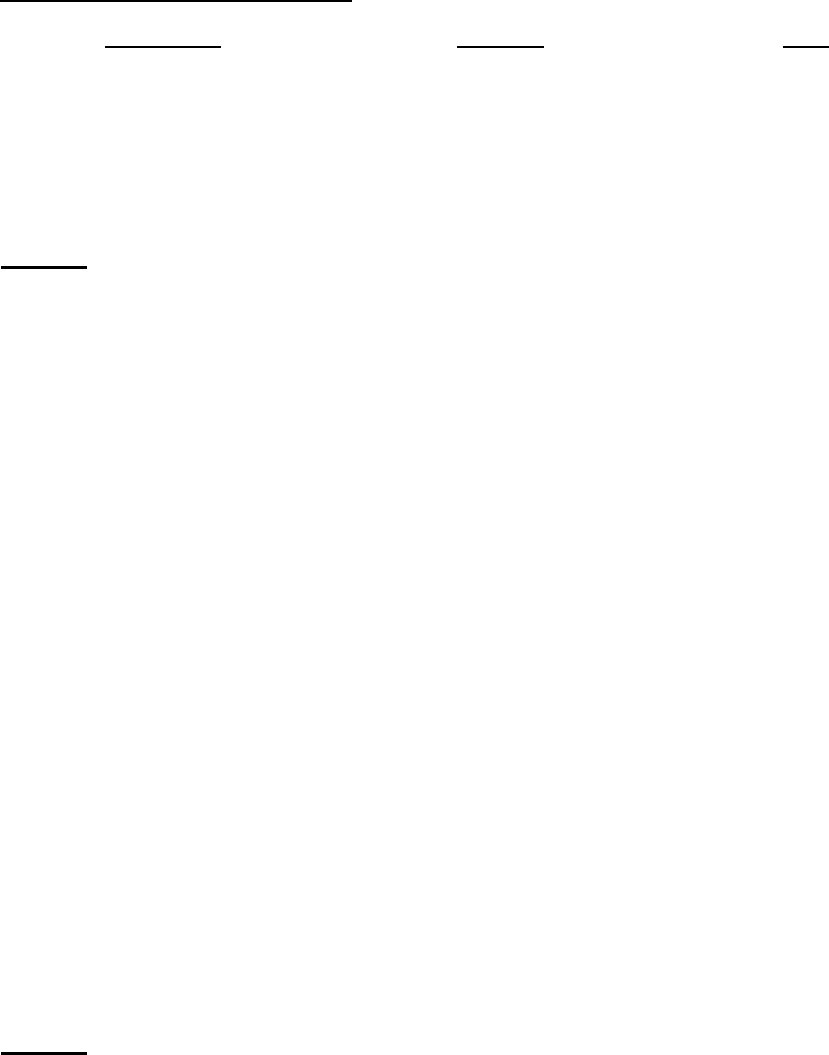

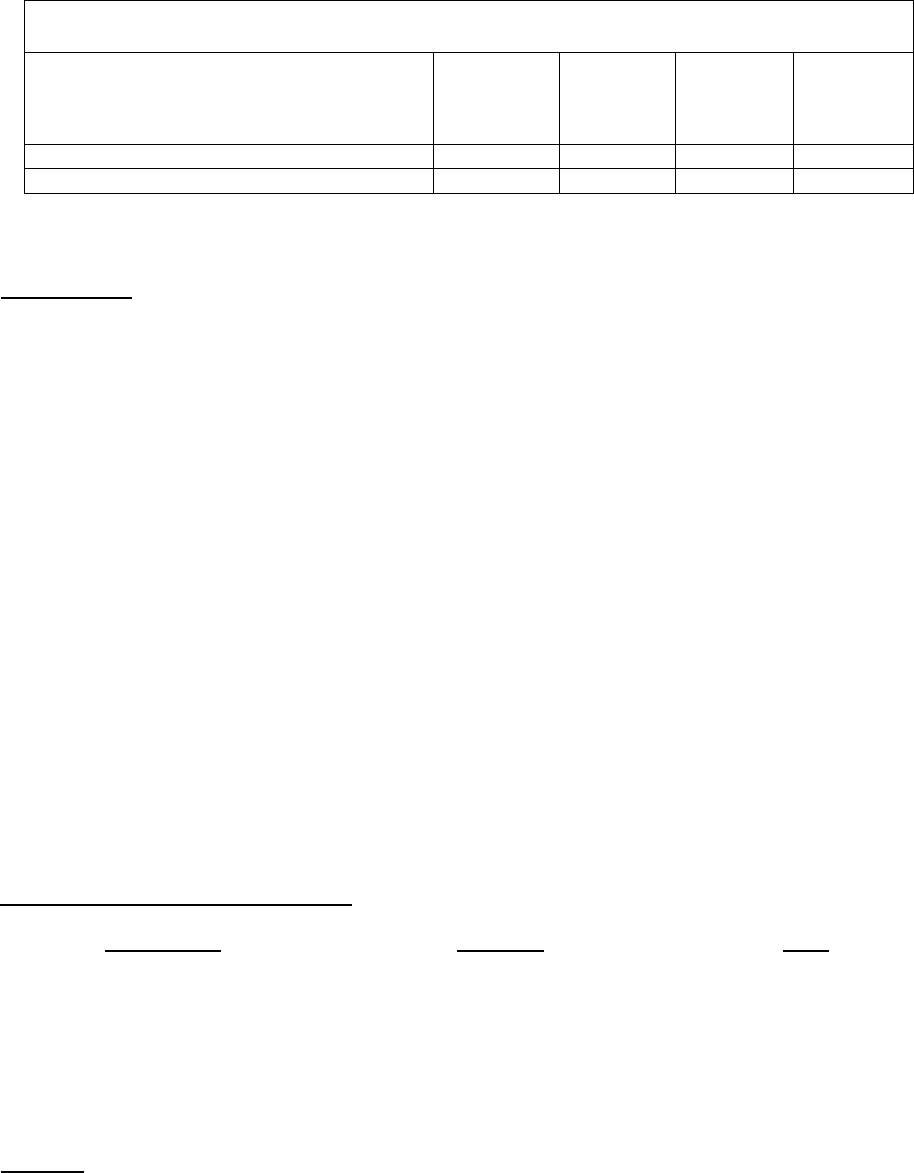

SUMMARY OF CHANGES

(Dollars in Thousands)

FY 2019

Enacted

FY 2020

Request

Net Change

Budget Authority

General Funds

$373,816

$376,043

+$2,227

Total

$373,816

$376,043

+$2,227

Full Time Equivalents

General Funds

1,984

1,984

0

Total

1,984

1,984

0

FY 2020 Change

Explanation of Change FY 2019 Base Trust Funds General Funds Total

FTE

Amount

FTE

Amount

FTE

Amount

FTE

Amount

Increases:

A. Built-Ins:

To Provide For:

Costs of pay adjustments

1,984

$178,082

0

$0

0

$0

0

$0

Personnel benefits

0

$63,568

0

$0

0

$0

0

$0

One day more of pay

0

$0

0

$0

0

$912

0

$912

Federal Employees' Compensation

Act (FECA)

0

$0

0

$0

0

$0

0

$0

Benefits for former personnel

0

$30

0

$0

0

$0

0

$0

Travel and transportation of persons

0

$10,399

0

$0

0

$0

0

$0

Transportation of things

0

$6,298

0

$0

0

$0

0

$0

Rental payments to GSA

0

$16,477

0

$0

0

$0

0

$0

Rental payments to others

0

$95

0

$0

0

$20

0

$20

Communications, utilities, and

miscellaneous charges

0

$2,691

0

$0

0

$0

0

$0

Printing and reproduction

0

$230

0

$0

0

$0

0

$0

Advisory and assistance services

0

$114

0

$0

0

$0

0

$0

Other services from non-Federal

sources

0

$5,017

0

$0

0

$0

0

$0

Working Capital Fund

0

$0

0

$0

0

$0

0

$0

Other Federal sources (DHS Charges)

0

$770

0

$0

0

$0

0

$0

Other goods and services from

Federal sources

0

$2,335

0

$0

0

$0

0

$0

Research & Development Contracts

0

$0

0

$0

0

$0

0

$0

Operation and maintenance of

facilities

0

$1,506

0

$0

0

$0

0

$0

Operation and maintenance of

equipment

0

$13,564

0

$0

0

$0

0

$0

Supplies and materials

0

$2,976

0

$0

0

$0

0

$0

Equipment

0

$2,951

0

$0

0

$0

0

$0

Grants, subsidies, and contributions

0

$10,787

0

$0

0

$0

0

$0

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 4

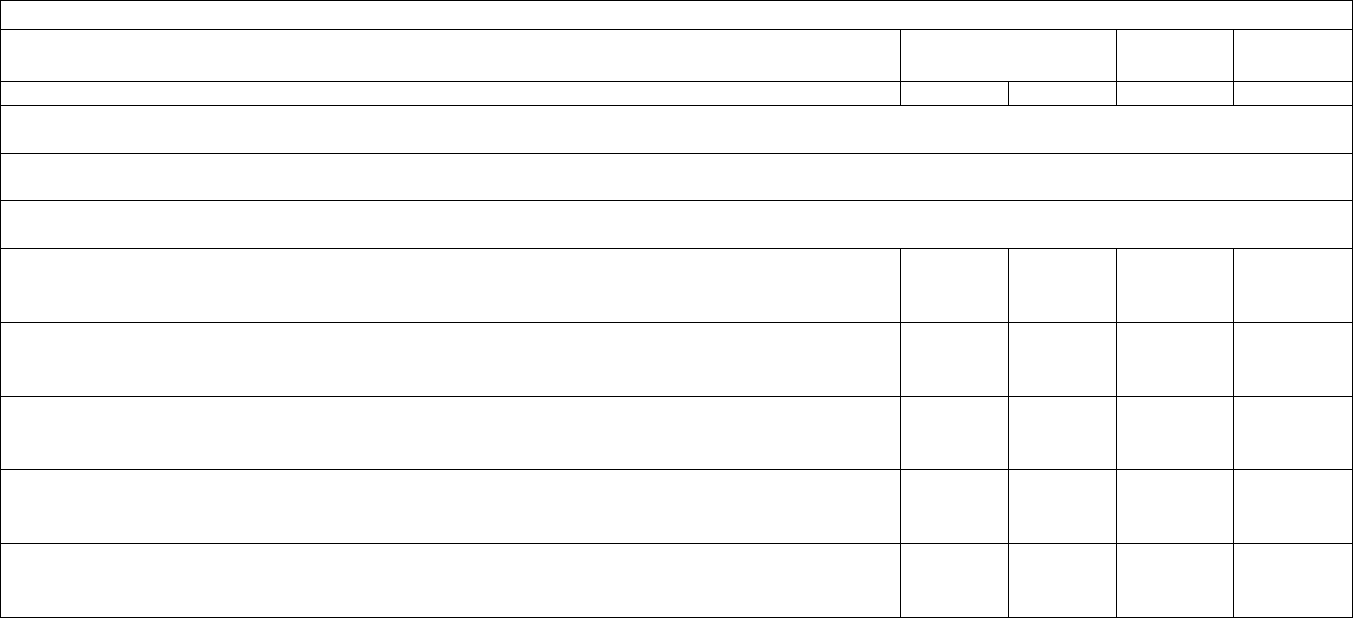

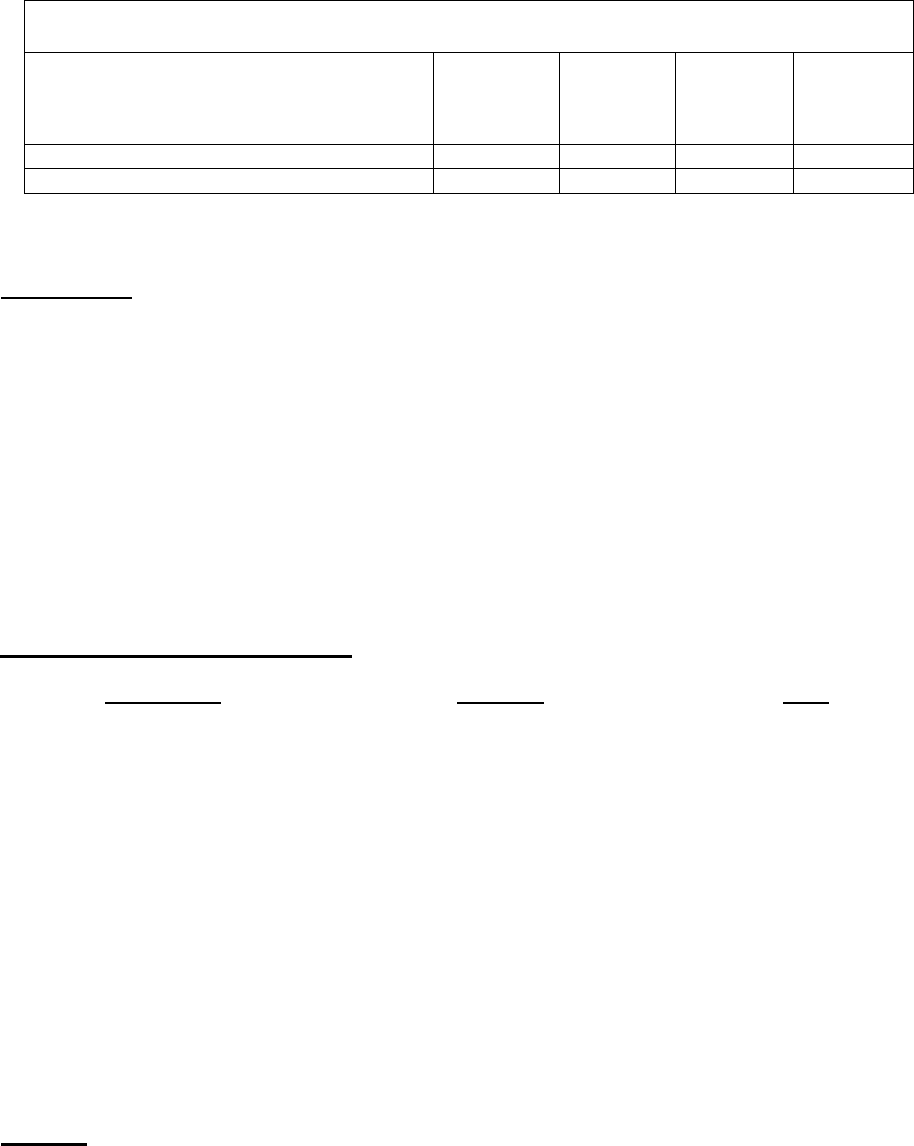

FY 2020 Change

Explanation of Change FY 2019 Base Trust Funds General Funds Total

FTE

Amount

FTE

Amount

FTE

Amount

FTE

Amount

Insurance claims and indemnities

0

$38

0

$0

0

$0

0

$0

Land and Structures

0

$0

0

$0

0

$0

0

$0

Built-Ins Subtotal

1,984

+$317,928

0

$0

0

+$932

0

+$932

B. Programs:

Create Mine Safety and Health

Enforcement

0

$0

0

$0

1,450

$252,913

1,450

$252,913

WCF-Worker Protection IT

Modernization Efforts

52

$19,083

0

$0

0

$2,500

0

$2,500

Programs Subtotal

0

$0

1,450

+$255,413

1,450

+$255,413

Total Increase

1,984

+$317,928

0

$0

1,450

+$256,345

1,450

+$256,345

Decreases:

A. Built-Ins:

To Provide For:

Federal Employees' Compensation

Act (FECA)

0

$7,551

0

$0

0

-$32

0

-$32

Working Capital Fund

0

$48,337

0

$0

0

-$105

0

-$105

Built-Ins Subtotal

0

+$55,888

0

$0

0

-$137

0

-$137

B. Programs:

Merging the Coal Mine Safety and

Health Budget Activity

866

$156,704

0

$0

-866

-$156,704

-866

-$156,704

Merging the Metal and Nonmetal

Mine Safety and Health Budget

Activity

584

$96,209

0

$0

-584

-$96,209

-584

-$96,209

Reduction to Absorb One More Day

of Pay and Inflationary Costs

534

$120,903

0

$0

0

-$795

0

-$795

Reduction in Enforcement

0

$0

0

$0

0

-$273

0

-$273

Programs Subtotal

0

$0

-

1,450

-$253,981

-

1,450

-$253,981

Total Decrease

0

+$55,888

0

$0

-

1,450

-$254,118

-

1,450

-$254,118

Total Change

1,984

+$373,816

0

$0

0

+$2,227

0

+$2,227

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 5

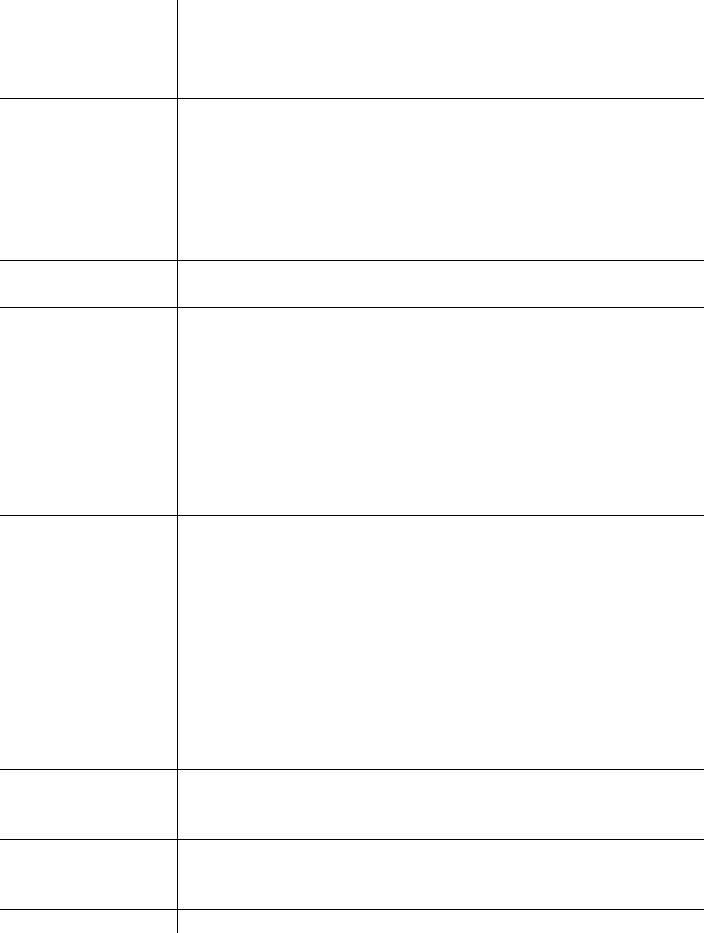

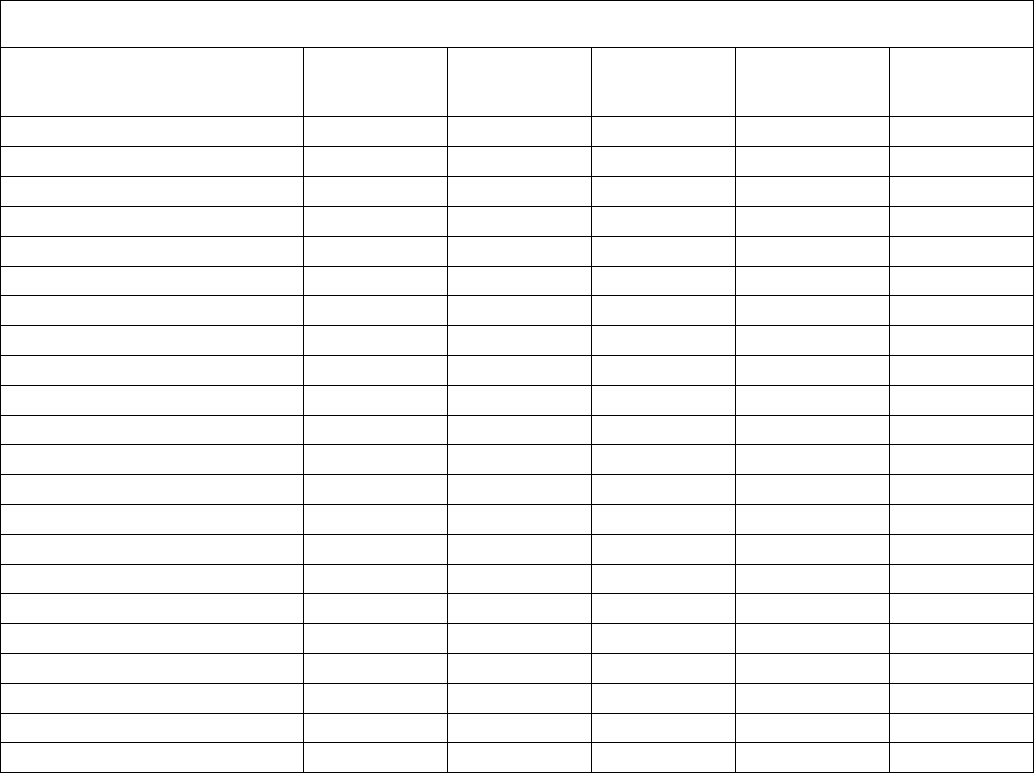

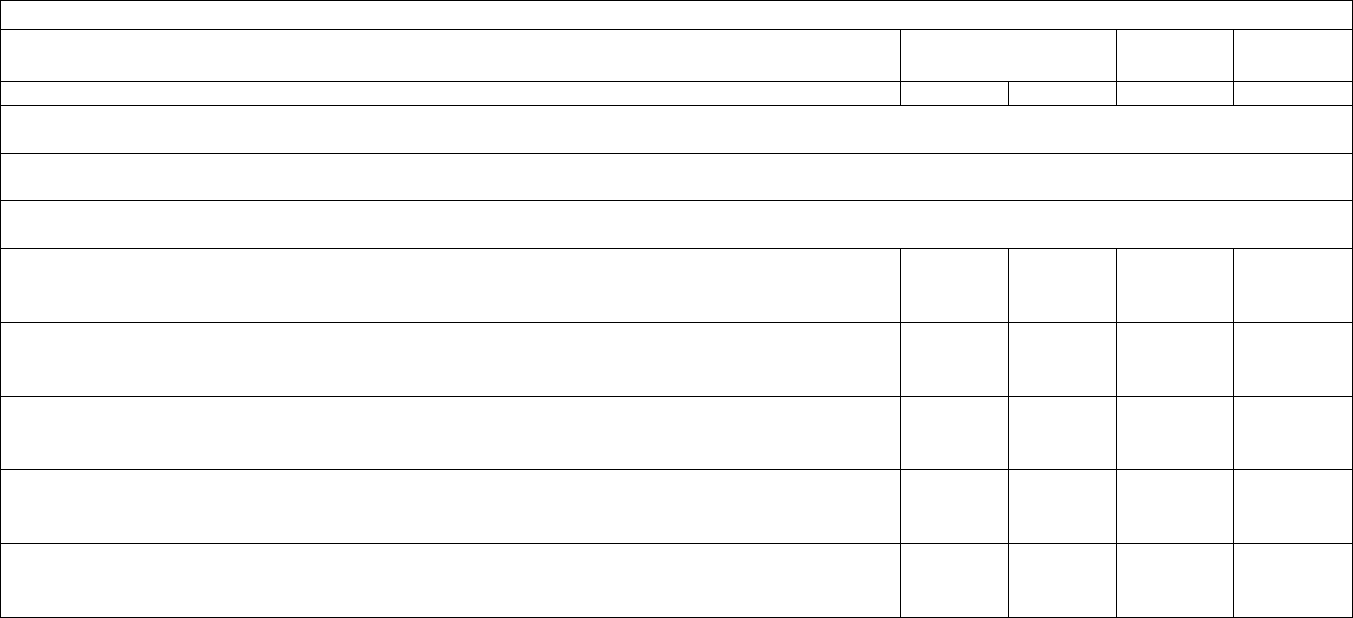

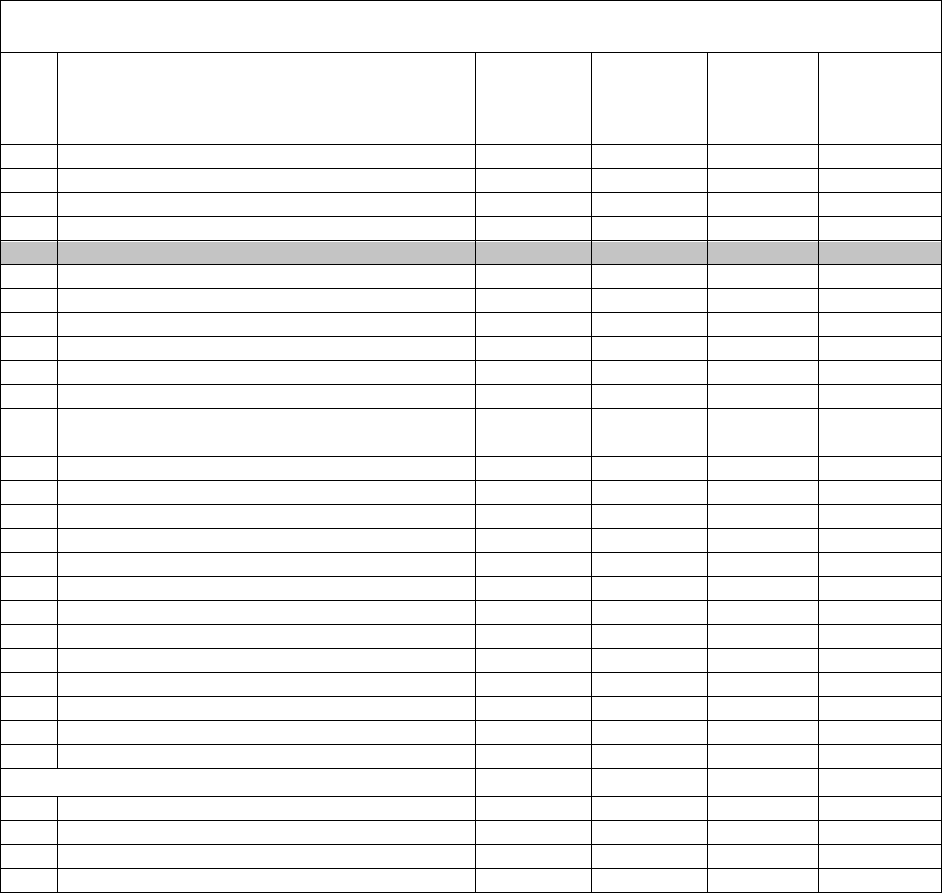

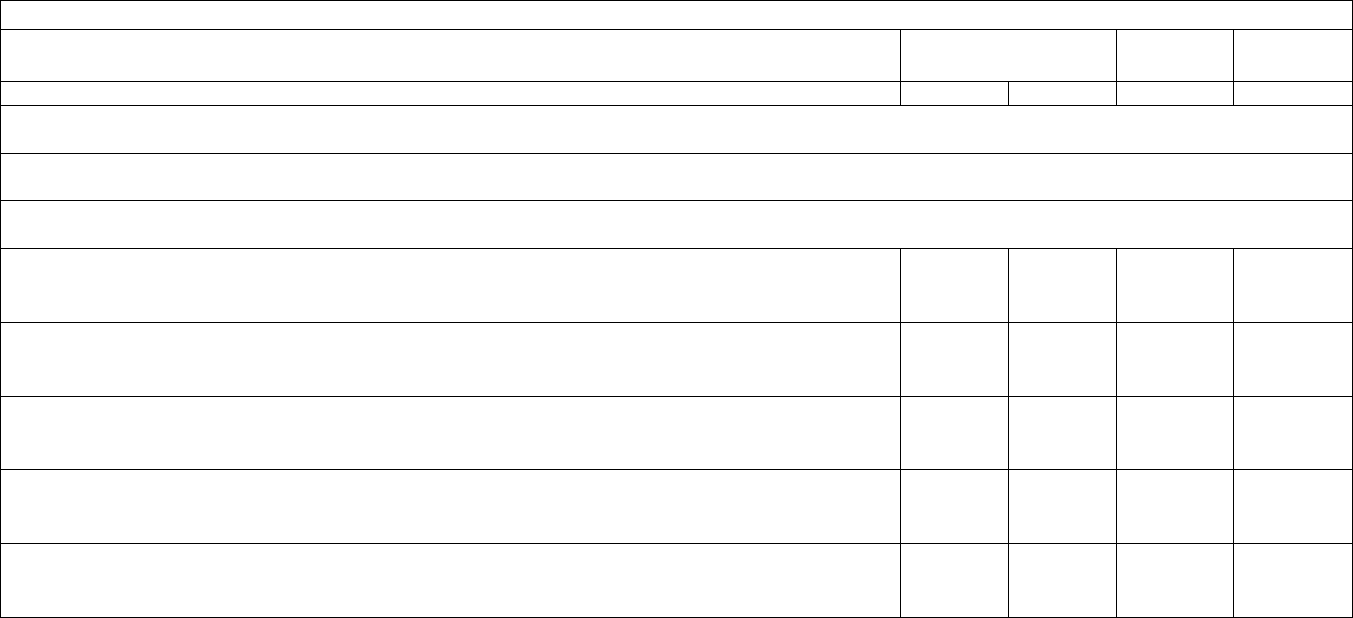

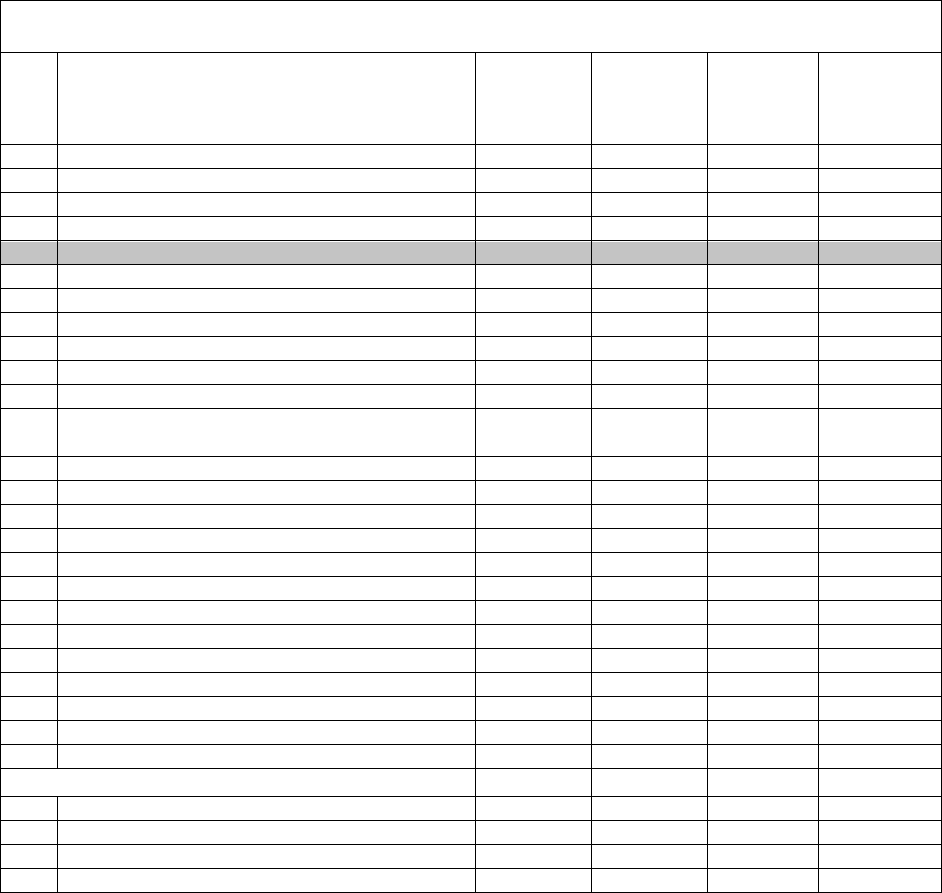

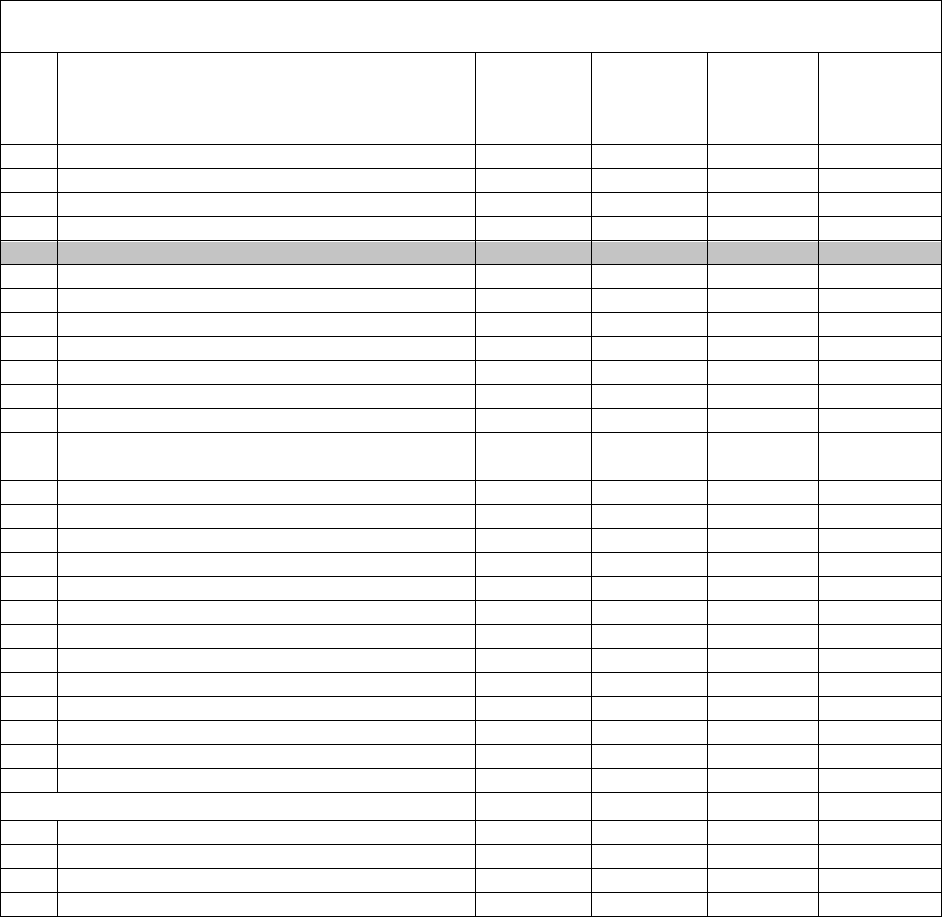

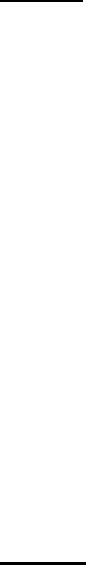

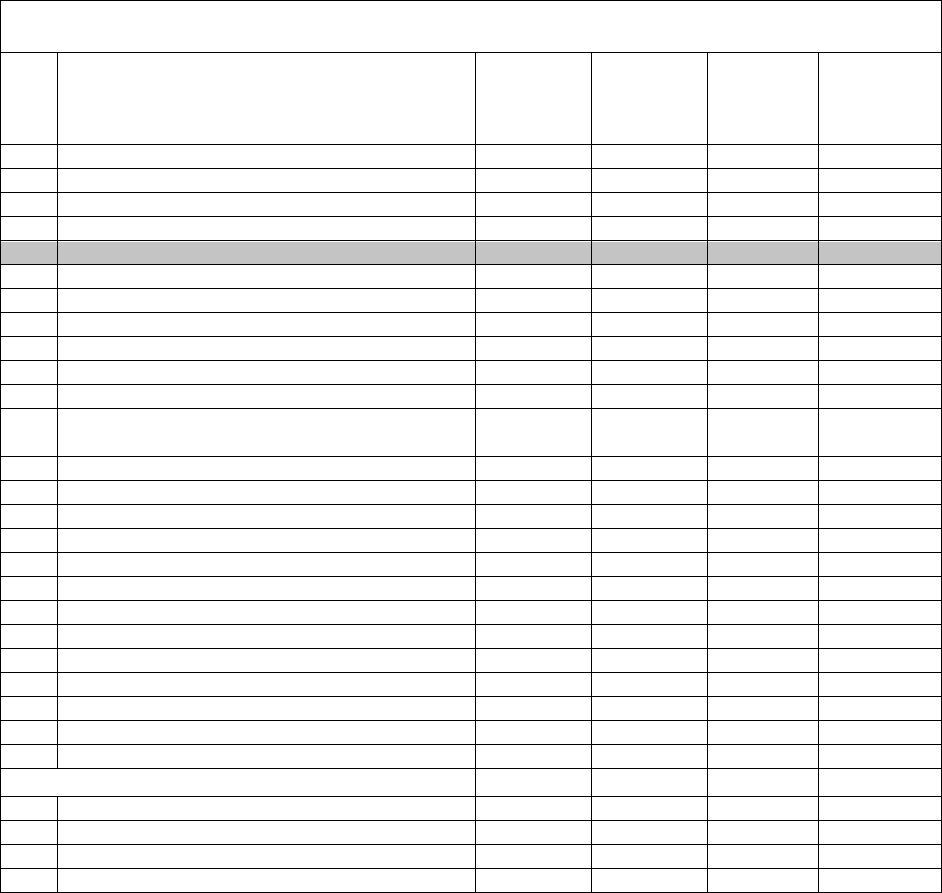

SUMMARY BUDGET AUTHORITY AND FTE BY ACTIVITY

(Dollars in Thousands)

FY 2018

1

Enacted

FY 2019

2

Enacted

FY 2020

Request

Diff. FY20 Request /

FY19 Enacted

FTE

Amount

FTE

Amount

FTE

Amount

FTE

Amount

Mine Safety and Health Enforcement

0

0

0

0

1,450

252,640

1,450

252,640

General Funds

0

0

0

0

1,450

252,640

1,450

252,640

Coal Mine Safety and Health

905

156,704

866

156,704

0

0

-866

-156,704

General Funds

905

156,704

866

156,704

0

0

-866

-156,704

Metal and Nonmetal Mine Safety and Health

554

96,209

584

96,209

0

0

-584

-96,209

General Funds

554

96,209

584

96,209

0

0

-584

-96,209

Office of Standards, Regulations, and Variances

16

5,382

19

5,382

19

5,382

0

0

General Funds

16

5,382

19

5,382

19

5,382

0

0

Office of Assessments

49

7,445

49

7,445

49

7,445

0

0

General Funds

49

7,445

49

7,445

49

7,445

0

0

Technical Support

201

34,079

205

34,079

205

34,079

0

0

General Funds

201

34,079

205

34,079

205

34,079

0

0

Educational Policy and Development

127

38,559

122

38,559

122

38,559

0

0

General Funds

127

38,559

122

38,559

122

38,559

0

0

1

FY 2018 Budget Authority reflects a reprogramming as reported in the Department’s budget operating plan.

2

FY 2019 Budget Authority reflects a reprogramming as reported in the Department’s budget operating plan.

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 6

SUMMARY BUDGET AUTHORITY AND FTE BY ACTIVITY

(Dollars in Thousands)

FY 2018

1

Enacted

FY 2019

2

Enacted

FY 2020

Request

Diff. FY20 Request /

FY19 Enacted

FTE

Amount

FTE

Amount

FTE

Amount

FTE

Amount

Program Evaluation and Information

Resources

51

19,083

52

19,083

52

21,583

0

2,500

General Funds

51

19,083

52

19,083

52

21,583

0

2,500

Program Administration

90

16,355

87

16,355

87

16,355

0

0

General Funds

90

16,355

87

16,355

87

16,355

0

0

Total

1,993

373,816

1,984

373,816

1,984

376,043

0

2,227

General Funds

1,993

373,816

1,984

373,816

1,984

376,043

0

2,227

NOTE: 2018 reflects actual FTE.

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 7

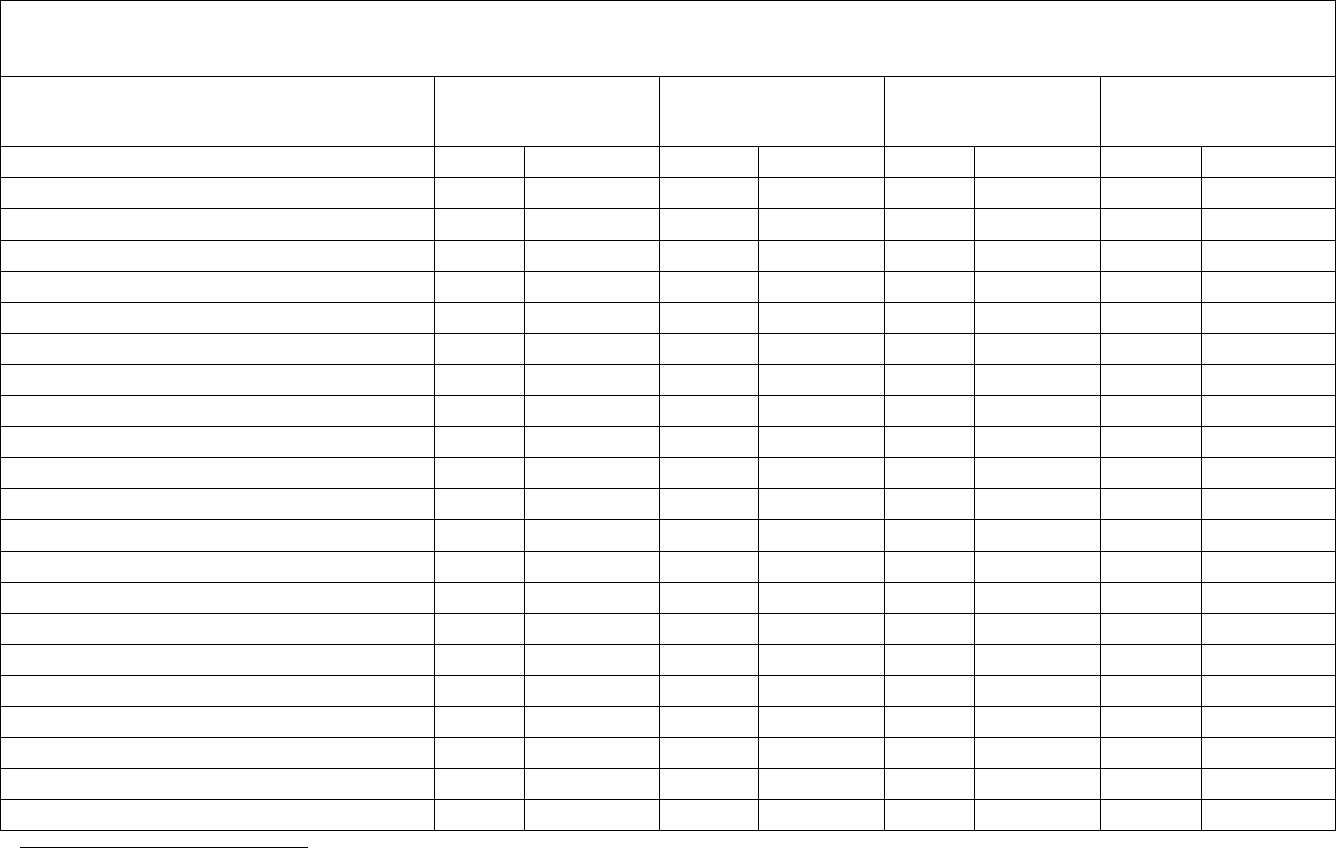

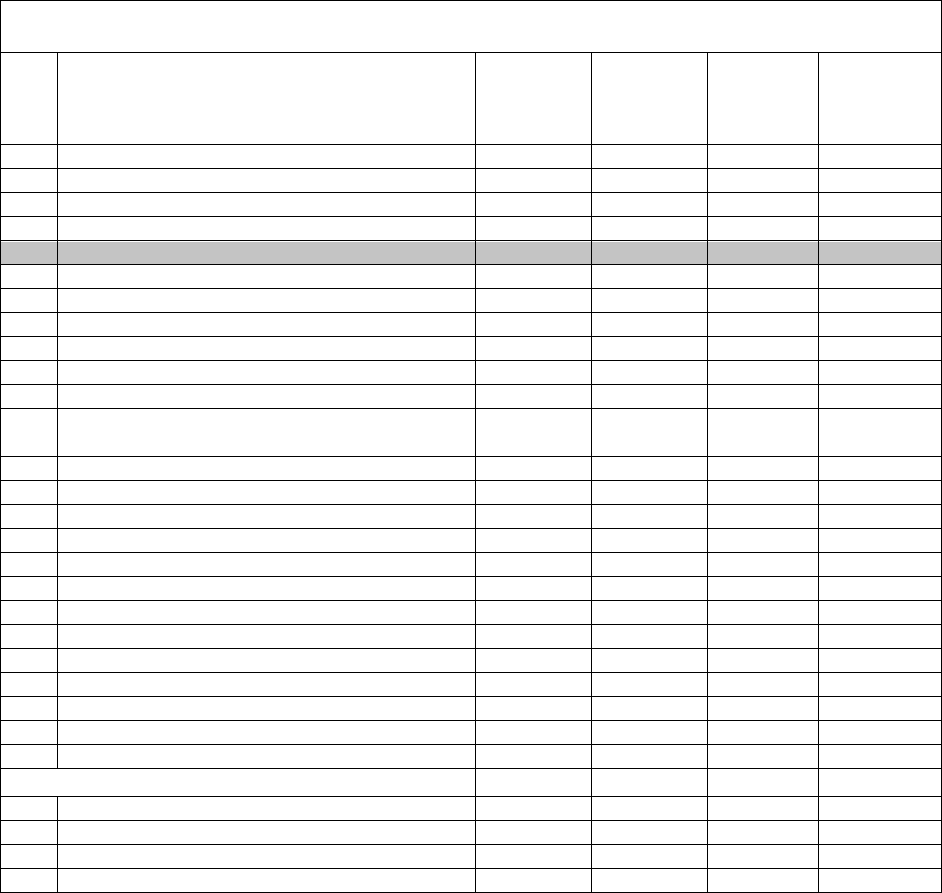

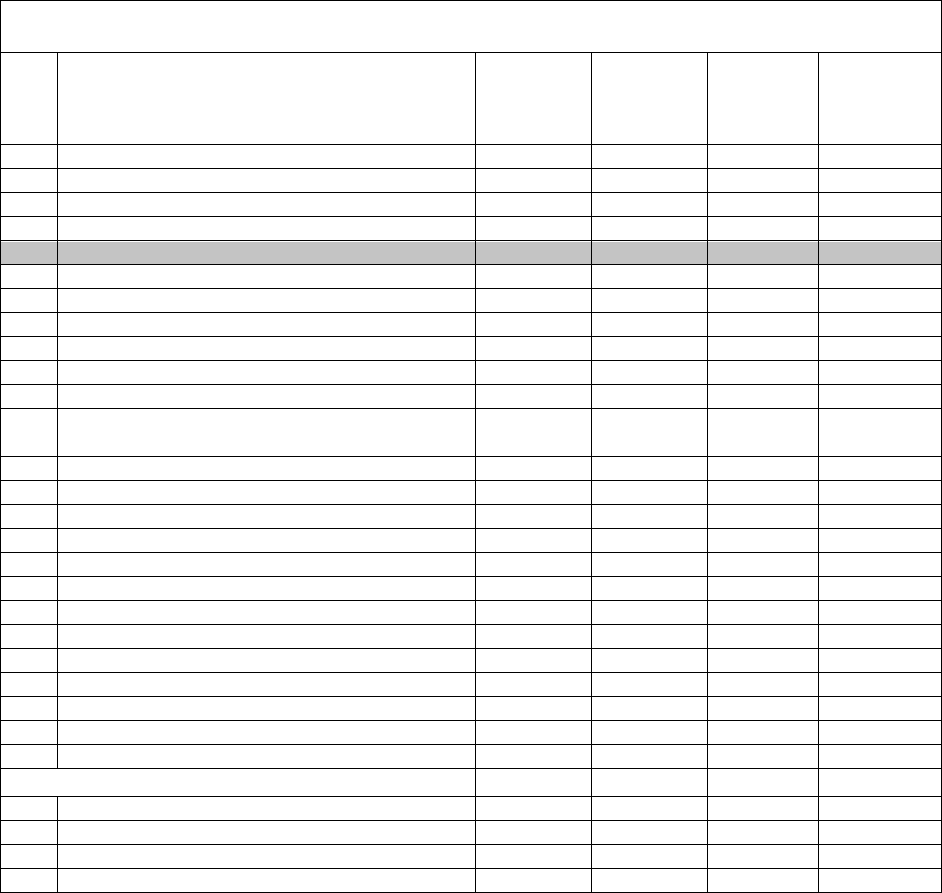

BUDGET AUTHORITY BY OBJECT CLASS

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Diff. FY20

Request /

FY19

Enacted

Full-Time Equivalent

Full-time Permanent

2,010

1,983

1,983

0

Other

13

1

1

0

Total

2,023

1,984

1,984

0

Average ES Salary

$183,480

$186,838

$190,388

$3,550

Average GM/GS Grade

11/5

11/5

11/5

0

Average GM/GS Salary

$85,090

$86,647

$88,293

$1,646

Average Salary of Ungraded Positions

54,260

55,253

56,303

1,050

11.1

Full-time permanent

173,404

174,269

174,269

0

11.3

Other than full-time permanent

180

105

818

713

11.5

Other personnel compensation

3,709

3,708

3,708

0

11.8

Special personal services payments

0

0

0

0

11.9

Total personnel compensation

177,293

178,082

178,795

713

12.1

Civilian personnel benefits

70,804

71,119

71,315

196

13.0

Benefits for former personnel

23

30

1

-29

21.0

Travel and transportation of persons

10,760

10,399

9,734

-665

22.0

Transportation of things

6,288

6,298

6,088

-210

23.0

Rent, Communications, and Utilities

0

0

0

0

23.1

Rental payments to GSA

17,769

16,477

16,477

0

23.2

Rental payments to others

80

95

115

20

23.3

Communications, utilities, and

miscellaneous charges

2,647

2,691

2,691

0

24.0

Printing and reproduction

272

230

230

0

25.1

Advisory and assistance services

169

114

114

0

25.2

Other services from non-Federal sources

4,637

5,017

4,893

-124

25.3

Other goods and services from Federal

sources 1/

51,768

51,442

53,837

2,395

25.4

Operation and maintenance of facilities

1,213

1,506

1,506

0

25.5

Research and development contracts

0

0

0

0

25.7

Operation and maintenance of equipment

11,705

13,564

13,564

0

26.0

Supplies and materials

2,585

2,976

2,976

0

31.0

Equipment

4,903

2,951

2,882

-69

32.0

Land and Structures

0

0

0

0

41.0

Grants, subsidies, and contributions

10,787

10,787

10,787

0

42.0

Insurance claims and indemnities

113

38

38

0

Total

373,816

373,816

376,043

2,227

1/Other goods and services from Federal sources

Working Capital Fund

48,027

48,337

48,232

-105

DHS Services

925

770

770

0

HHS Services

1,600

1,465

1,465

0

Services by Other Government

Departments

1,216

870

870

0

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 8

AUTHORIZING STATUTES

Public Law /

Act

Legislation

Statute No. /

US Code

Volume

No.

Page

No.

Expiration

Date

91-173

Federal Mine Safety and Health

Act of 1977, As Amended By

Public Law 95-164

30 U.S.C., 801 et.

seq.

30

823

None

109-236

Mine Improvement and New

Emergency Response Act of

2006 (MINER Act)

30 U.S.C., 801 et.

seq.

30

823

None

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 9

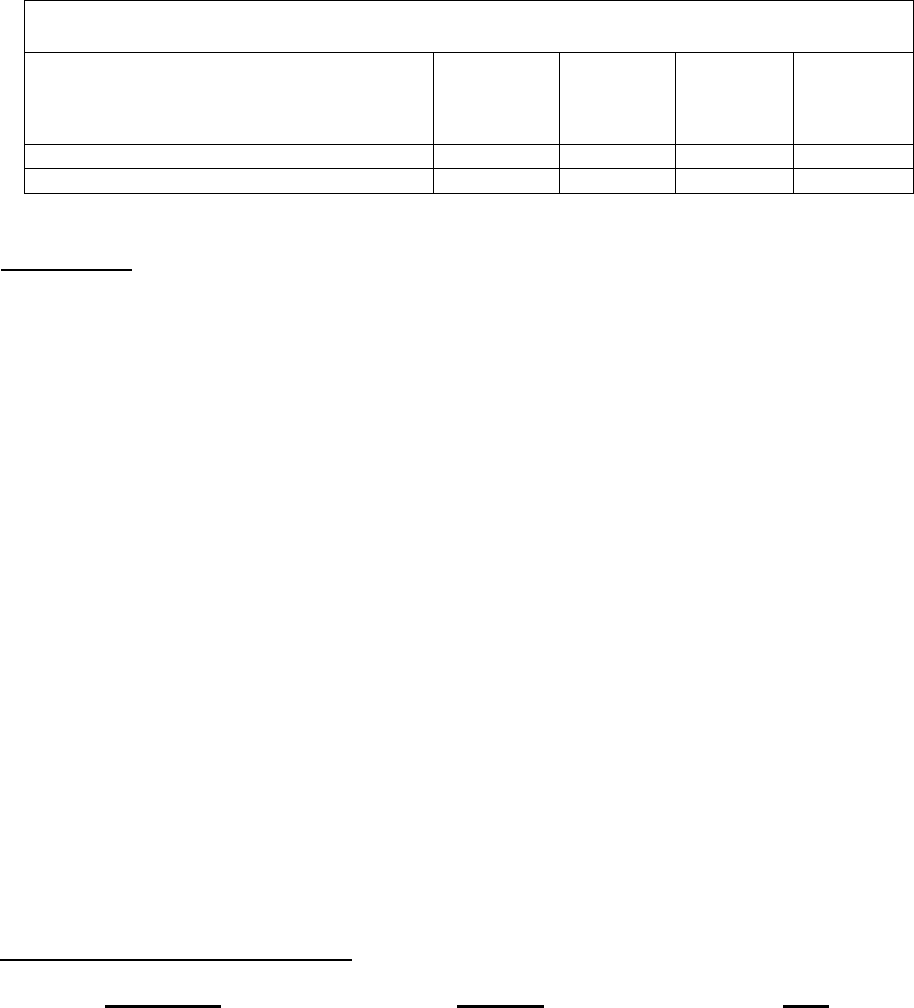

APPROPRIATION HISTORY

(Dollars in Thousands)

Budget

Estimates to

Congress

House

Allowance

Senate

Allowance

Appropriations

FTE

2010

Base Appropriation...1/

$353,693

$353,193

$357,443

$357,293

2,425

2011

Base Appropriation...2/

$360,780

$377,000

$363,115

2,328

2012

Base Appropriation...3/

$384,277

$379,854

$384,277

$373,293

2,365

2013

Base Appropriation...4/

$371,896

$353,768

2,388

2014

Base Appropriation

$380,721

$375,887

2,366

2015

Base Appropriation

$377,234

$375,887

2,316

2016

Base Appropriation

$394,932

$371,000

$356,878

$375,887

2,271

2017

Base Appropriation

$397,372

$373,816

2,152

2018

Base Appropriation...5/

$375,172

$359,975

$373,816

2,023

2019

Base Appropriation...6/

$375,906

$373,816

$373,816

1,984

2020

Base Appropriation

$376,043

1,984

1/ Does not include $7,259 provided to MSHA for the Upper Big Branch mine investigation and the caseload

backlog at the Federal Mine Safety and Health Review Commission in the Supplemental Appropriations Act,

P.L. 111-212. This amount was transferred from the Departmental Management account via a nonexpenditure

transfer.

2/ This bill was only reported out of Subcommittee and was not passed by the Full House. Reflects a $2,000 transfer

to the Office of the Solicitor.

3/ Reflects a $707 reduction pursuant to P.L. 112-74, and a $770 transfer to the Office of the Solicitor.

4/ Reflects a 0.2% across the board rescission pursuant to P.L. 113-6 and the sequestration reduction pursuant to the

Balanced Budget and Emergency Deficit Control Act of 1985.

5/ A full-year 2018 appropriation for this account was not enacted at the time the budget was prepared.

6/ This bill was passed by the Senate. It was passed out of the House Subcommittee but was not reported out of the House

Committee or by the full House.

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 10

OVERVIEW

Introduction

The Mine Safety and Health Administration (MSHA) works to prevent death, disease, and injury

from mining and promote safe and healthful workplaces for the nation’s miners. MSHA

enforces provisions of the Federal Mine Safety and Health Act of 1977 (Mine Act), as amended

by the Mine Improvement and New Emergency Response Act of 2006 (MINER Act).

More than 300,000 people work directly in the mining sector, including initial mining of raw

materials through processing in preparation for commercial distribution. This industry

provides essential materials for the nation's energy, power, transportation infrastructure,

construction and housing, communications, medicine, manufacturing, consumer goods, and

agricultural industries.

MSHA is committed to its mission and promotes safety and health through inspections and

enforcement, stakeholder outreach, compliance and technical assistance, education and

training, and improved safety and health standards. Effective approaches to reducing the risk

of injury and disease to miners include workplace examinations, hazard recognition and

elimination, and continual monitoring of the work environment to protect against new

hazards and to ensure compliance with safety and health standards. MSHA also protects the

rights of miners. The Mine Act gives miners the right to have a role in their safety and health

by participating in the inspection process through a representative of their choosing, speaking

out about hazards, refusing to work in dangerous conditions, and exercising other rights.

Since 2010, MSHA’s data indicate that work-related accidents at coal and metal and nonmetal

mines have declined, however, challenges remain. While the mining industry recorded the

lowest fatality rates in mining history in 2016, there was a small uptick in the number of fatalities

in 2017 and 2018. MSHA will utilize 2020 resources to reduce accidents, enforce safety and

health standards, provide compliance and technical assistance, and train miners and mine

operators on hazard recognition and elimination to decrease fatality and injury rates. Starting in

2018, MSHA focused its compliance and technical assistance efforts on reducing accidents

caused by powered haulage equipment, which continue to be a leading cause of mining fatalities.

MSHA continues to devote sufficient resources toward a competitive grant activity for effective

emergency response and recovery training in various types of mine conditions. MSHA will

measure the Agency performance of reducing the reportable injury rate associated with powered

haulage equipment by 10 percent per year. This performance goal is based on a rolling five-year

average per 200,000 hours worked. In FY 2018, the five-year rolling average of reportable

injuries was 0.19, the same as FY 2017.

Resources, Priorities, and Performance

In FY 2020, MSHA is requesting $376,043,000 and 1,984 FTE. This request builds on the FY

2019 Revised Enacted and reflects MSHA’s commitment to enforcement of the Mine Act and

providing compliance and technical assistance. MSHA’s budget includes discretionary program

changes listed below.

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 11

• Program increases:

o $252,913,000 and 1,450 FTE to create the Mine Safety and Health Enforcement

budget activity by merging the Coal Mine Safety and Health budget activity with

the Metal and Nonmetal Mine Safety and Health budget activity. The new

enforcement structure will provide the flexibility to address industry changes, and

maximize the efficient use of MSHA’s resources.

o $2,500,000 for MSHA to support the Department’s Worker Protection Agencies’

IT Modernization efforts. In total, the Department is requesting $20,000,000 for

this initiative with resources requested in the following appropriations: Employee

Benefits Security Administration, Office of Workers’ Compensation Programs,

Office of Federal Contract Compliance Programs, Office of Labor-Management

Standards, Wage and Hour Division, Occupational Safety and Health

Administration, Mine Safety and Health Administration, and the Office of the

Solicitor in the Departmental Management appropriation. These resources will be

managed by OCIO on behalf of the worker protection agencies and OCIO will

work in collaboration with the worker protection agencies to determine the

specific funding requirements and where funding can best support the

Department’s IT modernization efforts.

• Program decreases:

o $156,704,000 and 866 FTE for merging the Coal Mine Safety and Health

budget activity to create the Mine Safety and Health Enforcement budget

activity.

o $96,209,000 and 584 FTE for merging the Metal and Nonmetal Mine Safety

and Health budget activity to create the Mine Safety and Health Enforcement

budget activity.

o $273,000 to reduce funding within the Mine Safety and Health Enforcement

budget activity to account for economies of scale.

MSHA’s enforcement program supports the following President’s Management Agenda key

drivers and goals:

• IT Modernization - Enhance mission effectiveness by improving the quality and

efficiency of critical citizen-facing services, including through the increased

utilization of cloud-based solutions such as email and collaboration tools.

• Shifting from Low-Value to High-Value Work – By merging MSHA’s two

enforcement programs under a single Administrator, the Agency is providing needed

flexibility to address changing industry trends and is minimizing cost, and increasing

effectiveness and productivity. This is achieved by eliminating duplicative tasks and

focusing resources to ensure the Agency meets statutory obligations and high priority

initiatives to ensure the safety and health of our nation’s miners.

• People: Workforce for the 21st Century – Under MSHA’s new enforcement structure,

the Agency will be able to more efficiently use its experienced personnel and align

their skills to address evolving mission needs. MSHA’s inspector training programs

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 12

will be designed for a workforce that will inspect both coal and metal/nonmetal

underground and surface mines. Travel times between mining operations will

decrease, allowing for more onsite presence at mines.

MSHA will continue to meet the Agency’s statutory obligations under the Mine Act that include

completing its mandatory mine inspections -- four inspections per year in underground mines

and two inspections per year in surface mines, as well as enforcing mandatory health and safety

standards to protect the safety and health of the nation’s miners.

MSHA continues to identify ways to improve efficiency, effectiveness and accountability.

MSHA continues efforts to align the Agency’s organizational structure with its core mission and

operating plan, and focus on activities that will increase operational efficiency and provide

greater cost effectiveness. Additionally, MSHA continues to work with stakeholders to

strengthen collaborative relationships, to better understand the mining community’s needs, and

to develop guidance and outreach materials that will help to ensure miners’ safety and health.

MSHA will continue to evaluate the locations of mining activity and may assign mines to other

Districts to improve miners’ safety and health.

• MSHA recognizes the current trend in the coal industry and has taken actions to align

its resources accordingly. MSHA has closed three district offices and five field

offices since 2014. MSHA also plans to close the Jacksboro, Tennessee field office

location. Further, MSHA has shifted 75 employees from Coal Mine Safety and Health

to support Metal and Nonmetal Mine Safety and Health, Technical Support, and

Educational Policy and Development.

• MSHA anticipates that production will increase in several metal and nonmetal mining

sectors, particularly the aggregates, due to infrastructure revitalization, which would

require additional resources for enforcement, and compliance and technical

assistance. The Agency continues to monitor industry forecasts and will adjust

resources as necessary.

MSHA continues to work with the National Institute for Occupational Safety and Health

(NIOSH), industry, labor, and other stakeholders in the mining community to identify best

practices and new technologies that can improve miners’ safety and health. MSHA and NIOSH

will place particular focus collaborating on research priorities, so that research will be directed to

those issues that present the greatest hazards to miners’ safety and health. The MSHA/NIOSH

partnership continues to provide a forum for the exchange of scientific findings on the health

effects of diesel exhaust in underground mines. MSHA also has a number of industry alliances

through which it works to foster best practices and information sharing focused on health and

safety.

MINE SAFETY AND HEALTH ADMINISTRATION

MSHA - 13

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 15

BUDGET AUTHORITY BEFORE THE COMMITTEE

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Diff. FY20

Request /

FY19

Enacted

Activity Appropriation

0

0

252,640

252,640

FTE

0

0

1,450

1,450

Introduction

Historically, MSHA's enforcement function has been bifurcated into Coal and Metal/Nonmetal

program areas, each with its own Administrator and culture. MSHA has already consolidated the

two programs into one unified reporting structure with one Administrator. MSHA will create a

single enforcement budget activity, Mine Safety and Health Enforcement (MSHE), by

combining the Coal Mine Safety and Health (CMSH) budget activity with the Metal and

Nonmetal Mine Safety and Health (MNMSH) budget activity. MSHA will continue to evaluate

the field and district enforcement structures to better align agency resources with current mining

activity and to better allocate resources to improve mine safety such as providing increased

compliance assistance to small mines. Historically, MSHA's enforcement function has been

bifurcated into Coal and Metal/Nonmetal program areas, each with its own Administrator and

culture. MSHA is executing a gradual phase in approach merger by 2

nd

quarter FY 2020. The

merger will consist of two program areas, while still accommodating situations unique to certain

types of mines. MSHA will create a single enforcement budget activity, Mine Safety and Health

Enforcement (MSHE), by combining the Coal Mine Safety and Health (CMSH) budget activity

with the Metal and Nonmetal Mine Safety and Health (MNMSH) budget activity.

• The Administrator for MSHE will be supported by two Deputy Administrators: one for

CMSH and one for MNMSH.

• The new enforcement structure of MSHE will provide the needed flexibility to address

industry changes. MSHA acknowledges the long-term trends in coal production,

particularly in the Appalachian region, and estimates that production in several metal and

nonmetal mining sectors will increase due to infrastructure revitalization.

• MSHE will be able to make efficient use of the Agency’s cadre of experienced personnel,

and will be better able to ensure consistent enforcement and compliance assistance.

• MSHE will consist of a small headquarters office located in Arlington, Virginia. MSHA

will review office locations with respect to mining operations to ensure that districts and

field offices are located in areas that maximize efficient use of MSHA’s resources. The

Agency may consolidate district offices and field offices beginning in FY 2020 or earlier.

MSHE will administer the provisions of the Mine Act, as amended by the MINER Act, to

promote compliance with safety and health standards, prevent fatalities, reduce the frequency

and severity of accidents, and minimize health hazards in the nation’s approximately 1,200 coal

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 16

mines and 12,000 metal and nonmetal mines. MSHE inspects all active underground mines at

least four times per year and all surface mines twice per year. These inspections form the core of

MSHA’s efforts, regularly providing a first-hand look at conditions in each of the nation’s mines.

The majority of MSHE employees are located across 15 district offices and 89 field/satellite

offices throughout the United States and Puerto Rico. Most field employees are mine safety and

health enforcement personnel who perform inspection activities and investigations of fatal

accidents, non-fatal and non-injury accidents, verbal and written hazard complaints, and

discrimination complaints.

MSHE will continue efforts to improve workplace safety and health in the mining industry and

will remain committed to targeted enforcement and compliance assistance in its efforts to

improve safety and health conditions in the mining workplace by continuing the following

strategies:

• Enforcing mandatory health and safety standards through complete inspections of

each mine. MSHE will complete mandated inspections four times per year in

underground mines and twice per year in surface mines.

• Inspection and enforcement effectiveness. MSHE will enhance its enforcement efforts

of violations that contribute to fatalities and serious accidents through:

o Targeted inspections - MSHE will continue the Agency’s Targeted Inspections

initiative, as needed. These inspections target mines with specific conditions,

problems, or compliance issues.

o Promote adoption of prevention-focused, health and safety programs by

mine operators. MSHE will conduct health sampling activities to ensure that

miners’ overexposure to respirable dust, silica, and noise are addressed by mine

operators. Technical investigations, which evaluate the root causes of hazards

and accidents in mines, will be conducted. MSHE will also conduct accident

prevention inspections in response to specific mine hazards.

Protect miners from discrimination - MSHE will conduct timely investigations of

discrimination complaints and enhance miners’ knowledge regarding their rights and

responsibilities under the Mine Act.

FY 2020

In FY 2020, MSHA requests $252,640,000 and 1,450 FTE for MSHE. All program increases and

reductions are itemized below.

Program Change: $252,640,000 and 1,450 FTE to create the Mine Safety and Health

Enforcement (MSHE) budget activity by merging the Coal Mine Safety and Health (CMSH)

budget activity with the Metal and Nonmetal Mine Safety and Health (MNMSH) budget activity.

This includes a reduction $273,000 to account for economies of scale within the Mine Safety and

Health Enforcement budget activity. The reductions is attributable to travel.

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 17

Program

Total

FTE

CMSH

$156,704,000

866

MNMSH

$96,209,000

584

Decrease

($273,000)

Total

$252,640,000

1,450

Funding will support MSHA’s continued efforts to encourage the mining community to develop

and implement safety and health programs and to use an integrated approach toward the

prevention of serious accidents, injuries and occupational illnesses in the mining industry. In

FY 2020, MSHE will continue to ensure safe and healthful workplaces for the nation’s miners

through the following:

• Conduct all regular mandated inspections;

• Conduct targeted inspections;

• Provide compliance assistance;

• Conduct comprehensive health inspections;

• Conduct accident investigations (including root cause analyses);

• Perform accident prevention and outreach activities;

• Educate miners to enable them to exercise their rights and protections; and

• Conduct investigations of safety and discrimination complaints made by miners or their

representative.

MSHE projects that it will conduct approximately 20,200 mandated inspections. The actual

number of mandated inspections completed will depend on the number of operating mines.

MSHE will conduct other enhanced enforcement activities, such as targeted inspections. These

inspections target not only mines with a poor compliance history, but also those that have

adverse conditions such as increased methane liberation. The program will focus inspection

activity on improved impoundment safety by conducting inspections of all impoundments

classified as high-hazard potential.

MSHE will continue to enforce health standards to prevent occupational illnesses in the mining

industry. The elimination of black lung disease will continue to be a priority. MSHE will

continue to enforce the standards to reduce miners’ exposure to respirable coal mine dust; to

review the quality of coal mine dust controls in mine ventilation and dust control plans; and to

monitor operator sampling equipment in conjunction with regular inspections. MSHE will also

continue to share best practices for controlling exposures to respirable dust, quartz/silica and

noise.

MSHE will conduct compliance assistance activities to prevent fatalities, injuries, and

occupationally-related illnesses. These activities include assisting mine operators in solving

difficult health and safety problems, distributing training materials to mine operators, conducting

seminars, and speaking on mine health and safety in critical areas. MSHE will offer these

services especially to small mine operators, contractors, and miners who have not received

adequate training. It will continue to provide compliance assistance to new mine operators,

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 18

which often employ less experienced miners and need additional initial assistance to establish

safe and healthful workplaces.

MSHE will continue to conduct accident and technical investigations, including root cause

analyses. These investigations will allow MSHE to analyze accidents to identify conditions and

practices that contribute to injuries and deaths such as safety standards violated, root causes, and

abatement practices. MSHE will also perform accident prevention and outreach activities such

as Winter Alert campaign, Spring Thaw workshops, the Preventive Roof/Rib Outreach Program,

and Powered Haulage Outreach.

MSHE will investigate hazard complaints and miner discrimination complaints in a timely

manner. MSHE will continue to educate miners on their rights under the Mine Act through its

outreach programs.

MSHE will continue to provide entry-level training programs for new inspectors, and retraining

every two years for journeyman inspectors. In addition, field office supervisors will attend a

two-week training program. All new supervisors will attend appropriate training as required by

DOL. MSHA will continue to utilize technology such as video teleconferencing and online

courses to provide some of the training as a cost-effective method of delivery.

MSHE will also begin to implement regular mine safety inspection efficiencies. Currently

MSHA conducts full inspections at mines that have entered into active non-producing status.

Mines are considered to be in active non-producing status when the work of all miners has been

terminated and production related activities has ceased. In FY 2020, MSHA will begin to reduce

inspection hours spent at mines in active non-producing status. MSHA estimates that

recalibrating to a lower level of inspection would achieve projected savings of 25 FTE while

maintaining the same level of safety and health. MSHA will recalibrate to a full inspection as a

mine enters and exits active non-producing status, with less than full but appropriate levels of

periodic inspections in the interim, to ensure safety for any miners who maintain such a mine.

FY 2019

See the CMSH and MNMSH budget activity narratives.

FY 2018

See the CMSH and MNMSH budget activity narratives.

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 19

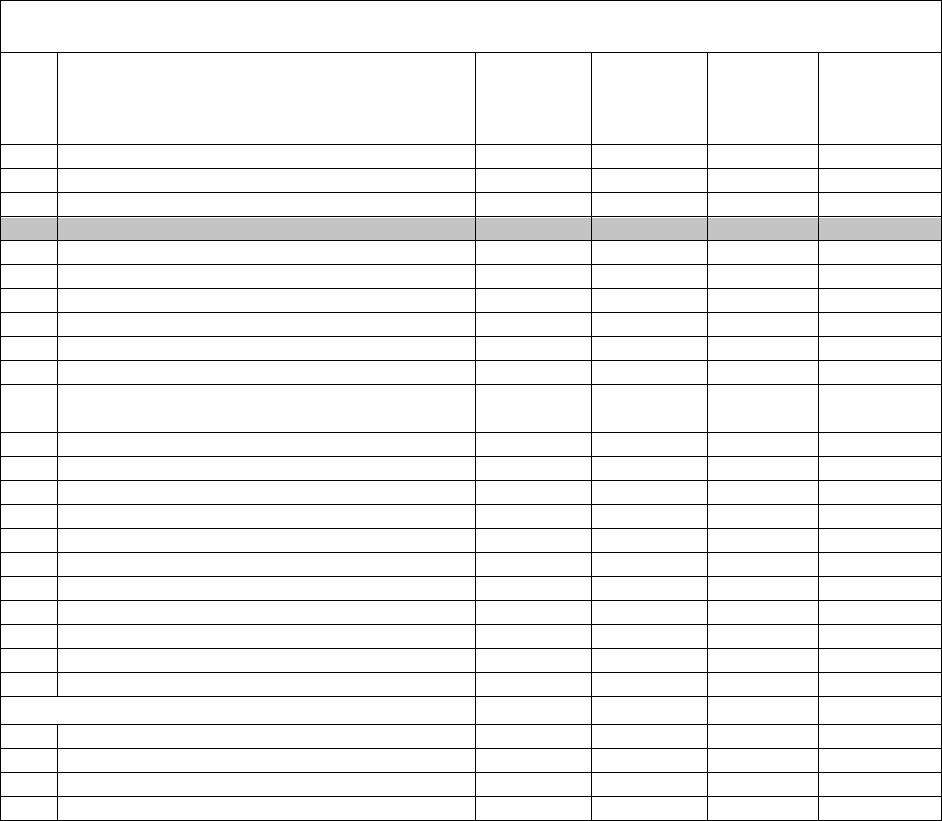

WORKLOAD AND PERFORMANCE SUMMARY

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Target

Result

Target

Target

Mine Safety and Health Enforcement

Strategic Goal 2 - Promote Safe Jobs and Fair Workplaces for All Americans

Strategic Objective MSHA 2.2 - Prevent fatalities, disease, and injury from mining, and secure safe and healthful working conditions for America's miners.

MSHA-

INSP1.1

Percent of regular mandated underground inspections

-- -- -- 100%

MSHA-

INSP2.1

Percent of regular mandated surface inspections

-- -- -- 100%

MSHA-01.1

Percent of 105(c) investigations of miner discrimination complaints that are completed

within 60 days of receipt -- -- -- 85%

MSHA-02.1

Percent of investigations of miner requests for temporary reinstatements that are

completed within 20 days of receipt -- -- -- 75%

MSHA-03.1

Number of 103(g) imminent danger complaint investigations initiated within 1 day of

receipt -- -- -- 100%

Legend:

(r) Revised

(e) Estimate

(base) Baseline

-- Not Applicable

TBD - To Be Determined

[p] - Projection

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 20

MSHE will implement its enforcement strategies and initiatives through the following:

• MSHA-INSP1 and MSHA-INSP2: In FY 2020, MSHE projects it will complete 100

percent of its regular mandated inspections. These inspections provide an examination of

mining conditions and play a key role in assuring the safety and health of the nation's

miners. The actual number of surface and underground inspections completed will

depend on the number of active mines for each year. The projected number of

underground and surface mandated inspections in FY 2020 is 20,200. MSHE will

conduct targeted inspections at mines with poor compliance history or that have adverse

conditions such as increased methane liberation. MSHE will inspect all existing high-

hazard potential impoundments during regular mandated inspections in order to reduce

the risk to miners, the general public, and the environment should these impoundments

fail.

The Mine Act gives miners the right to participate in their safety and health by participating in

the inspection process through a representative of their choosing, speaking out about hazards,

refusing to work in dangerous conditions, and exercising other rights. MSHE will continue to

ensure that all miner requests for temporary reinstatements, investigations of 105(c) miner

discrimination complaints, and 103(g) imminent danger complaints are investigated within the

established timeframes. Prompt investigation of discrimination complaints and reported

hazardous conditions is of utmost importance in assuring miners that MSHA will protect their

rights through the following efforts in FY 2020:

• MSHA-01: Complete 85 percent of 105(c) investigations of miner discrimination

complaints within 60 days of receipt of a complaint.

•

MSHA-02: Complete 85 percent of investigations of miner requests for temporary

reinstatement within 20 days of receipt.

• MSHA-03: Initiate 100 percent of 103(g) imminent danger complaint investigations

within one day of receipt.

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 21

BUDGET ACTIVITY BY OBJECT CLASS

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Diff. FY20

Request /

FY19

Enacted

11.1

Full-time permanent

0

0

123,330

123,330

11.3

Other than full-time permanent

0

0

522

522

11.5

Other personnel compensation

0

0

2,759

2,759

11.9

Total personnel compensation

0

0

126,611

126,611

12.1

Civilian personnel benefits

0

0

53,360

53,360

13.0

Benefits for former personnel

0

0

0

0

21.0

Travel and transportation of persons

0

0

8,714

8,714

22.0

Transportation of things

0

0

5,561

5,561

23.1

Rental payments to GSA

0

0

13,833

13,833

23.2

Rental payments to others

0

0

36

36

23.3

Communications, utilities, and miscellaneous

charges

0

0

840

840

24.0

Printing and reproduction

0

0

36

36

25.1

Advisory and assistance services

0

0

14

14

25.2

Other services from non-Federal sources

0

0

356

356

25.3

Other goods and services from Federal sources 1/

0

0

35,798

35,798

25.4

Operation and maintenance of facilities

0

0

8

8

25.7

Operation and maintenance of equipment

0

0

3,540

3,540

26.0

Supplies and materials

0

0

1,903

1,903

31.0

Equipment

0

0

2,027

2,027

42.0

Insurance claims and indemnities

0

0

3

3

Total

0

0

252,640

252,640

1/Other goods and services from Federal sources

Working Capital Fund

0

0

33,885

33,885

DHS Services

0

0

636

636

HHS Services

0

0

610

610

Services by Other Government Departments

0

0

667

667

MINE SAFETY AND HEALTH ENFORCEMENT

MSHA - 22

CHANGES IN FY 2020

(Dollars in Thousands)

Activity Changes

Built-In

To Provide For:

Costs of pay adjustments

$0

Personnel benefits

0

One day more of pay

657

Federal Employees' Compensation Act (FECA)

-25

Benefits for former personnel

0

Travel and transportation of persons

0

Transportation of things

0

Rental payments to GSA

0

Rental payments to others

6

Communications, utilities, and miscellaneous charges

0

Printing and reproduction

0

Advisory and assistance services

0

Other services from non-Federal sources

0

Working Capital Fund

-76

Other Federal sources (DHS Charges)

0

Other goods and services from Federal sources

0

Operation and maintenance of facilities

0

Operation and maintenance of equipment

0

Supplies and materials

0

Equipment

0

Insurance claims and indemnities

0

Built-Ins Subtotal

$562

Net Program

$252,078

Direct FTE

1,450

Estimate

FTE

Base

$562

0

Program Increase

$252,913

1,450

Program Decrease

-$835

0

COAL MINE SAFETY AND HEALTH

MSHA - 23

BUDGET AUTHORITY BEFORE THE COMMITTEE

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Diff. FY20

Request /

FY19

Enacted

Activity Appropriation

156,704

156,704

0

-156,704

FTE

905

866

0

-866

NOTE: FY 2018 reflects actual FTE. Authorized FTE for FY 2018 was 933.

Introduction

Coal Mine Safety and Health (CMSH) administers the provisions of the Mine Act, as amended

by the MINER Act, promotes compliance with safety and health standards to prevent fatalities,

reduces the frequency and severity of accidents, and minimizes health hazards in the nation’s

approximately 1,200 coal mines. CMSH inspects all active underground mines at least four

times per year and all surface mines twice per year. These inspections form the core of MSHA’s

enforcement, regularly providing a first-hand look at conditions in each of the nation’s mines.

Most of the CMSH employees are located across 9 district offices and 37 field offices throughout

the United States. The majority of field employees are mine safety and health enforcement

personnel who perform inspection activities and investigations, including investigations of fatal

accidents, non-fatal and non-injury accidents, verbal and written hazard complaints, and

discrimination complaints.

CMSH will continue efforts to improve workplace safety and health in the mining industry by

continuing the following strategies:

• Enforcing mandatory safety and health standards. CMSH will complete mandated

inspections four times per year in underground coal mines and twice per year at surface

coal mines.

• Inspection and enforcement effectiveness. CMSH will continue to enhance its

enforcement efforts of violations that contribute to fatalities and serious accidents

through:

o Targeted inspections - CMSH will continue the Agency’s Targeted Inspections

initiative on an as needed basis. These inspections target mines with specific

conditions, problems, or compliance issues.

o Promote adoption of prevention-focused, health and safety programs by

mine operators. CMSH will continue its health sampling activities to ensure that

miners’ overexposure to respirable dust, silica, and noise are addressed by mine

operators. Compliance assistance initiatives will focus on identified issues.

Technical investigations, which evaluate the root causes of hazards and accidents

in mines, will be conducted. CMSH will also conduct accident prevention

inspections in response to specific mine hazards.

COAL MINE SAFETY AND HEALTH

MSHA - 24

o Reduce Powered Haulage Accidents. CMSH will continue the Agency’s

initiative to reduce accidents associated with powered haulage equipment using a

collaborative approach involving MSHA program areas and mine safety

stakeholders.

• Protect miners from discrimination - CMSH will conduct timely investigations of

discrimination complaints and enhance miners’ knowledge regarding their rights and

responsibilities under the Mine Act. During outreach efforts, it will distribute educational

materials to ensure that miners are aware of their rights and responsibilities under the

Mine Act, without fear of retaliation.

Five-Year Budget Activity History

Fiscal Year

Funding

(Dollars in Thousands)

FTE

2015

$167,859

1,151

2016

$167,859

1,099

2017

$160,000

995

2018

$156,704

933

2019

$160,000

887

FY 2020

In FY 2020, MSHA will create a single enforcement budget activity (Mine Safety and Health

Enforcement) by merging CMSH and the MNMSH.

FY 2019

CMSH will continue an integrated approach toward the prevention of serious accidents, injuries

and occupational illnesses in the coal mining industry. CMSH will continue to ensure safe and

healthful workplaces for the nation’s miners through the following:

• Conduct all regular mandated inspections;

• Enforce respirable dust standards;

• Conduct targeted inspections;

• Perform accident prevention and outreach activities including various aspects of powered

haulage;

• Perform accident investigations (including root cause analyses);

• Conduct special initiatives to address particular issues;

• Conduct investigations of safety and discrimination complaints made by miners or their

representatives.

CMSH estimates that it will conduct approximately 3,150 mandated inspections, but this number

may vary depending on the number of operating mines. CMSH will conduct other enhanced

enforcement activities, such as targeted inspections. These inspections target not only mines

with a poor compliance history, but also those that have adverse conditions such as increased

COAL MINE SAFETY AND HEALTH

MSHA - 25

methane liberation and miners’ overexposures to silica. The program will focus inspection

activity on improved impoundment safety by conducting inspections of all impoundments

classified as high-hazard potential. CMSH will also focus its efforts on mine operators that fail

to meet dust and noise standards.

CMSH will continue to enforce health standards to reduce miners’ exposure to respirable coal

mine dust. The standard reduces the allowable amount of respirable dust to which a miner can

be exposed as well as increases the frequency of dust sampling and requires coal operators to

take immediate action when dust levels exceed the standard. MSHA will continue to update and

share best practices for controlling exposures to respirable dust, quartz/silica, and noise.

CMSH will continue to conduct accident and technical investigations, including root cause

analyses. These investigations will allow CMSH to analyze accidents to identify conditions and

practices that contribute to injuries and deaths such as safety standards violated, root causes, and

abatement practices. CMSH will also perform accident prevention and outreach activities such

as Winter Alert campaign and the Preventive Roof/Rib Outreach Program.

CMSH will investigate hazard complaints and miner discrimination complaints in a timely

manner. CMSH will continue to educate miners on their rights under the Mine Act through its

outreach programs. CMSH will also continue to encourage miners to report hazards through the

use of the MSHA.gov website, MSHA's National Hazard Reporting Page, and the 1-800 “One

Call Does It All” phone number. This is critical in reducing safety and health risks. CMSH will

continue to encourage an industry-wide culture in which mine operators take ownership of health

and safety through effective prevention-oriented health and safety management programs;

conduct thorough inspections and robust enforcement; promote stakeholder outreach, education,

and training; and propose improved regulations.

CMSH and MNMSH will begin to merge program functions and train all relevant personnel.

Classroom and on-the-job training will be provided to inspectors and management personnel.

The FY 2019 journeyman retraining will focus on the “crossover” training.

FY 2018

In FY 2018, CMSH completed 100 percent of its regular mandated underground and surface

inspections. It also conducted 53 targeted inspections resulting in 524 citations, 10 orders, and 2

safeguards, for a total of 536 issuances and a Significant and Substantial rate of 23 percent.

These inspections targeted not only mines with compliance issues, but also hazards pertaining to

the transportation of miners and materials in underground coal mines, and specific areas of

concern such as increased methane liberation, rock dust sampling, belt conveyors, and roof

control.

CMSH continued to reallocate resources from areas in which trends indicated a shift in mining.

This reallocation was accomplished through attrition, personnel transfers, and district office

closures. In FY 2018, CMSH finalized the closure of District 11 in Birmingham, AL, and

initiated plans to close the McHenry, MD field office in District 3 by FY 2020.

COAL MINE SAFETY AND HEALTH

MSHA - 26

CMSH conducted special emphasis respirable coal mine dust inspections as needed. CMSH

continued to enforce the standards and inspection requirements established in the Respirable

Dust Rule.

CMSH continued to conduct accident investigations, including root cause analyses. These

investigations allowed CMSH to analyze fatal accidents to identify conditions and practices that

contributed to injuries and deaths. CMSH also performed accident prevention and outreach

activities.

CMSH investigated 795 miner hazard complaints with 315 positive findings in a timely manner.

CMSH received 45 complaints of discrimination complaints. Of these cases, 19 complainants

requested temporary reinstatement. The Secretary filed eleven applications for temporary

reinstatement of discharged miners.

MSHA announced that it would be gradually merging CMSH and MNMSH into one

enforcement program. Preparation began by selecting mines and training inspectors to conduct

the initial crossover inspections. Implementation started October 1, 2018, and selected

approximately 90 primarily small, less complex metal and nonmetal mines to be inspected by

CMSH inspectors and five coal mines to be inspected by MNMSH Inspectors.

COAL MINE SAFETY AND HEALTH

MSHA - 27

WORKLOAD AND PERFORMANCE SUMMARY

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Target

Result

Target

Target

Coal Mine Safety and Health

Strategic Goal 2 - Promote Safe Jobs and Fair Workplaces for All Americans

Strategic Objective MSHA 2.2 - Prevent fatalities, disease, and injury from mining, and secure safe and healthful working conditions for America's miners.

MSHA-01

Percent of 105(c) investigations of miner discrimination complaints that are completed

within 60 days of receipt 85% 94% 85% --

MSHA-CM-

01.1

Number of regular mandated coal underground inspections

1,200 1,216 1,200 --

MSHA-CM-

01.2

Number of regular mandated coal surface inspections

2,000 1,964 1,950 --

MSHA-02

Percent of investigations of miner requests for temporary reinstatements that are

completed within 20 days of receipt 75% 90% 75% --

MSHA-03

Number of 103(g) imminent danger complaint investigations initiated within 1 day of

receipt 100% 100% 100% --

Legend:

(r) Revised

(e) Estimate

(base) Baseline

-- Not Applicable

TBD - To Be Determined

[p] - Projection

COAL MINE SAFETY AND HEALTH

MSHA - 28

CMSH will continue enforcement strategies and initiatives through the following:

• MSHA-INSP1and MSHA-INSP2: CMSH projects it will complete 100 percent of its

regular mandated inspections. The actual number of surface and underground inspections

completed will depend on the number of active coal mines for each year. CMSH will

conduct targeted inspections at mines with a poor compliance history or that have adverse

conditions.

The Mine Act gives miners the right to have a role in their safety and health by participating in

the inspection process through a representative of their choosing, speaking out about hazards,

refusing to work to work in dangerous conditions, and exercising other rights. These efforts

support workers’ rights through the following in FY 2019:

• MSHA-01: Complete 85 percent of 105(c) investigations of miner discrimination

complaints within 60 days of receipt of a complaint.

• MSHA-02: Complete 85 percent of investigations of miner requests for temporary

reinstatement within 20 days of receipt.

• MSHA-03: Initiate 100 percent of 103(g) imminent danger complaint investigations

within one day of receipt.

COAL MINE SAFETY AND HEALTH

MSHA - 29

BUDGET ACTIVITY BY OBJECT CLASS

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Diff. FY20

Request /

FY19

Enacted

11.1

Full-time permanent

74,660

72,914

0

-72,914

11.3

Other than full-time permanent

5

0

0

0

11.5

Other personnel compensation

1,773

1,715

0

-1,715

11.8

Special personal services payments

0

0

0

0

11.9

Total personnel compensation

76,438

74,629

0

-74,629

12.1

Civilian personnel benefits

33,915

33,160

0

-33,160

13.0

Benefits for former personnel

8

29

0

-29

21.0

Travel and transportation of persons

1,654

1,586

0

-1,586

22.0

Transportation of things

2,827

2,942

0

-2,942

23.1

Rental payments to GSA

9,315

8,648

0

-8,648

23.2

Rental payments to others

40

20

0

-20

23.3

Communications, utilities, and miscellaneous

charges

361

354

0

-354

24.0

Printing and reproduction

61

23

0

-23

25.1

Advisory and assistance services

16

10

0

-10

25.2

Other services from non-Federal sources

288

188

0

-188

25.3

Other goods and services from Federal sources 1/

28,591

31,286

0

-31,286

25.4

Operation and maintenance of facilities

12

8

0

-8

25.5

Research and development contracts

0

0

0

0

25.7

Operation and maintenance of equipment

510

2,214

0

-2,214

26.0

Supplies and materials

678

745

0

-745

31.0

Equipment

1,877

861

0

-861

41.0

Grants, subsidies, and contributions

0

0

0

0

42.0

Insurance claims and indemnities

113

1

0

-1

Total

156,704

156,704

0

-156,704

1/Other goods and services from Federal sources

Working Capital Fund

26,988

30,114

0

-30,114

DHS Services

479

397

0

-397

HHS Services

495

378

0

-378

Services by Other Government Departments

629

397

0

-397

COAL MINE SAFETY AND HEALTH

MSHA - 30

CHANGES IN FY 2020

(Dollars in Thousands)

Activity Changes

Built-In

To Provide For:

Costs of pay adjustments

$0

Personnel benefits

0

One day more of pay

0

Federal Employees' Compensation Act (FECA)

0

Benefits for former personnel

0

Travel and transportation of persons

0

Transportation of things

0

Rental payments to GSA

0

Rental payments to others

0

Communications, utilities, and miscellaneous charges

0

Printing and reproduction

0

Advisory and assistance services

0

Other services from non-Federal sources

0

Working Capital Fund

0

Other Federal sources (DHS Charges)

0

Other goods and services from Federal sources

0

Research & Development Contracts

0

Operation and maintenance of facilities

0

Operation and maintenance of equipment

0

Supplies and materials

0

Equipment

0

Grants, subsidies, and contributions

0

Insurance claims and indemnities

0

Built-Ins Subtotal

$0

Net Program

-$156,704

Direct FTE

-866

Estimate

FTE

Base

$156,704

866

Program Increase

$0

0

Program Decrease

-$156,704

-866

METAL AND NONMETAL MINE SAFETY AND HEALTH

MSHA - 31

BUDGET AUTHORITY BEFORE THE COMMITTEE

(Dollars in Thousands)

FY 2018

Enacted

FY 2019

Enacted

FY 2020

Request

Diff. FY20

Request /

FY19

Enacted

Activity Appropriation

96,209

96,209

0

-96,209

FTE

554

584

0

-584

NOTE: FY 2018 reflects actual FTE. Authorized FTE for FY 2018 was 558.

Introduction

Metal and Nonmetal Mine Safety and Health (MNMSH) administers the Mine Act as amended

by the MINER Act, and promotes compliance with safety and health standards to prevent

fatalities, reduce the frequency and severity of accidents, and minimize health hazards in the

nation’s approximately 12,000 metal and nonmetal mines. MNMSH inspects all active

underground mines at least four times per year and surface mines twice per year. These

inspections form the core of MSHA’s enforcement, regularly providing a first-hand look at

conditions in each of the nation’s mines.

Most of the MNMSH employees are located across six district offices and 52 field/satellite

offices throughout the United States and Puerto Rico. The majority of field employees are mine

safety and health professionals who perform inspection activities and investigations, including

investigations of fatal accidents, non-fatal and/or non-injury accidents, verbal and written hazard

complaints, and discrimination complaints.

MNMSH remains committed to targeted enforcement and compliance assistance and will

continue to improve safety and health conditions in the mining workplace through the following

strategies:

• Enforcing mandatory safety and health standards. MNMSH will continue to conduct

mandated inspections twice per year in metal and nonmetal surface mines and four times

per year in underground mines.

• Increase inspection and enforcement effectiveness - MNMSH will continue to enhance

enforcement efforts for violations of the standards associated with fatalities and serious

accidents, with emphasis on powered haulage accidents. MNMSH will continue its focus

on improving dam safety by continuing inspection activity at dams classified as high-

hazard potential.

o Targeted inspections - MNMSH will continue to conduct targeted inspections.

The actual number of inspections will depend on how many mines need additional

inspections. MNMSH will not conduct inspections in order to meet a specific

number.

o MNMSH Health Program - MNMSH will continue to conduct health

inspections at mines. It will place emphasis on mine operators’ responsibility for

METAL AND NONMETAL MINE SAFETY AND HEALTH

MSHA - 32

conducting required health surveys to determine adequate control measures and

explore additional innovative initiatives to effectively address the health program.

o Reduce Powered Haulage Accidents. MNMSH will continue the Agency’s

initiative to reduce accidents associated with powered haulage equipment using a

collaborative approach involving MSHA program areas and mine safety

stakeholders.

Protect miners from discrimination - MNMSH will continue to ensure that all miners’

discrimination complaints are investigated within established timeframes. During outreach

efforts, it will distribute educational materials to ensure that miners are aware of their rights and

responsibilities under the Mine Act, without fear of retaliation.

Five-Year Budget Activity History

Fiscal Year

Funding

(Dollars in Thousands)

FTE

2015

$91,697

586

2016

$91,697

598

2017

$94,500

589

2018

$96,209

558

2019

$94,500

573

FY 2020

MSHA proposes to merge the MNMSH budget activity with the Coal Mine Safety and Health

(CMSH) budget activity in FY 2020. See the FY 2020 write-up within the Mine Safety and

Health Enforcement budget activity narrative.

FY 2019

MNMSH will continue an integrated approach toward the prevention of serious accidents,

injuries and occupational illnesses in the mining industry. MNMSH will continue to ensure safe

and health the workplaces for the nation’s miners through the following:

• Conduct all of its regular mandated inspections;

• Conduct targeted inspections;

• Conduct comprehensive health inspections;

• Perform accident prevention and outreach activities including various aspects of powered

haulage;

• Perform accident investigations (including root cause analyses);

• Conduct investigations of safety and discrimination complaints made by miners or their

representatives.

METAL AND NONMETAL MINE SAFETY AND HEALTH

MSHA - 33

MNMSH will conduct over 16,300 inspections. These include over 16,000 regular mandated

inspections, as well as other enforcement activities, including investigations of hazard

complaints, special investigations and accident investigations, spot inspections, and follow-up

visits. The actual number of mandated inspections completed will depend on the number of

operating mines. Spot inspections will be based on reported injuries and occupational illnesses,

and investigations of safety and discrimination complaints made by miners or their

representatives. MNMSH will also focus on improving dam safety by increasing inspection

activity at the dams classified as high-hazard potential.

MNMSH will continue its target Inspection program. MNMSH will select mines for target

inspections based on several criteria, including compliance and accident and injury history.

These targets are data-driven and subject to change dependent on mining industry data and

performance.

Miners must be free to exercise their right to identify hazardous conditions and request MSHA

inspections without fear of retaliation or discrimination. MNMSH will continue to encourage

miners to report hazards through the use of the MSHA.gov website, MSHA's National Hazard

Reporting Page, and the 1-800 “One Call Does It All” phone number. This is critical in reducing

safety and health risks. MNMSH special investigators will continue to monitor, manage, and

reduce the time to process miner discrimination complaints and complete investigations of

knowing and willful violations. MSHA will continue to demonstrate to miners its commitment

to protect their right to report health and safety hazards without fear of retaliation.

MNMSH estimates that it will conduct health inspections at a minimum of 20 percent of mines

under its jurisdiction. Inspections will assess the effectiveness of controls and sampling

programs through data collection, observations of mining cycle and work practices, interviews,

plan reviews, and sampling. The data collected forms the basis of appropriate enforcement

actions as well as assuring that mine operators are adequately protecting miners from

overexposures to airborne contaminants.

MSHA will continue to provide entry-level training programs for new inspectors, and retraining

every two years for journeyman inspectors. In addition, field office supervisors will attend a

two-week training program. All new supervisors will attend appropriate training as required by

DOL. MSHA will continue to utilize technology such as video teleconferencing and online

courses to provide some of the training as a cost-effective method of delivery. CMSH and

MNMSH will begin to merge program functions and train all relevant personnel. Classroom

and on-the-job training will be provided to inspectors and management personnel. The FY 2019

journeyman retraining will focus on the “crossover” training.

FY 2018

The metal and nonmetal mining sector experienced 12 fatal accidents, the lowest number

recorded for a fiscal year in MSHA's history. MNMSH believes that this is due in large part to

the number of inspectors available at mine sites conducting inspections and compliance

assistance “walk and talks,” and participation in stakeholder/miner outreach and prevention-

focused activities.

METAL AND NONMETAL MINE SAFETY AND HEALTH

MSHA - 34

MNMSH completed 100 percent of its regular mandated underground and surface inspections in

FY 2018. MNMSH exceeded its estimate of conducting health inspections at mines under its

jurisdiction. MNMSH received 1,209 hazardous condition complaints during FY 2018, which

442 had positive findings. It completed 51 targeted inspections at metal and nonmetal mines,

resulting in 503 citations and 22 orders.

MNMSH continued to roll out a number of prevention-focused activities, including outreach

with stakeholders and utilizing the agency’s training and enforcement tools. MNMSH has taken

a number of measures to prevent mining deaths, injuries and illnesses: increased surveillance and

strategic enforcement through target inspections at mines with troubling complaint histories;

special initiatives such as “Powered Haulage,” which focuses attention on the most common fatal

accident classification.

MNMSH developed a Compliance and Policy Updates section on MSHA’s website in an effort

to promote consistency within MSHA and to provide guidance for the mining industry. Items

posted included Policy Information Bulletins, Program Policy Letters, and answers to frequently

asked questions.

MNMSH fostered and maintained alliances with metal and nonmetal mining associations across

the country and arranged and/or participated in stakeholder summits and outreach activities with

the associations.

MNMSH continued to inform the industry and miners of their rights and responsibilities, and

conducted timely investigations of 103(g) imminent danger complaints, 105(c) investigations of

miner discrimination complaints, and miner requests for temporary reinstatements.

MNMSH received 55 complaints of discrimination under Section 105(c) of the Mine Act. Of

these cases, 29 complainants requested temporary reinstatement. The Secretary filed five

applications for temporary reinstatement of discharged miners.

MSHA announced that it would be “gradually merging CMSH and MNMSH into one

enforcement program. Preparation began by selecting mines and training inspectors to conduct